Keppel DHCS Pte Ltd

Keppel DHCS is known as the largest provider of district heating and cooling systems in Singapore. The company has implemented energy-saving measures at three of its DCS plants in response to stronger national environmental protection measures and in order to reinforce its business competitiveness by reducing operational costs of their facilities. The company has achieved figures well above its preset energy targets while minimizing both investment and risk by adopting an approach of making use of the plants’ existing facilities and developing measures based on an ESCO plan.

Factories and Plants Water and Sewerage Energy Efficiency Industrial Automation Control and Monitoring Systems and Software

Products/Services Provided

A Road Map for the Next Decade of Energy Savings Being the Key to Business Success

In the early 19th century, Singapore became UK’s trading hub in the East and its prosperity has been based predominantly on the transit trade between India and China taking place there. For some time now, Singapore has been ranked among the top in the world in terms of GDP and continues to grow economically with its high ability to compete in international markets. Keppel Corporation, a government-linked company developing its business in a wide range of industries, such as infrastructure, real estate, marine, and investment, plays a role in Singapore’s development. Being a member of such company, Keppel DHCS Pte Ltd is recognized as the largest DHCS*1 provider in Singapore.

Today, Keppel DHCS owns four DCS*1 plants located in four different districts of Changi, Woodlands, Biopolis, and Mediapolis in Singapore. Keppel DHCS has a DHCS plant in Tianjin, China, and is making positive efforts to expand its business in Indonesia and other Southeast Asian regions as well.

In recent years, the Singapore government has been focusing its efforts on promoting energy efficiency in the building field as in industry, and has been working on various initiatives by, for example, implementing the BCA Green Mark Scheme*2 to assess environmentallyfriendly buildings. “The assessment applies to DCS plants, so we had to meet the energy requirements for our plants also. But of course, it is true that implementing energy-saving measures increases efficiency and reduces energy cost, which leads to reinforcement of our business foundations. So from a few years ago, we started to draw up a road map for the next 10 years of energy savings at our DCS plants,” says Mr. Ng.

Ideas Incorporating Optimal Control and ESCO Plan in Order to Minimize the Risk of Initial Investment

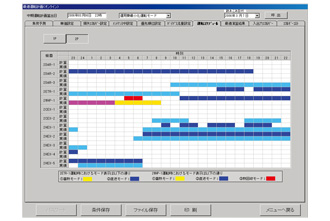

The Harmonas-DEO system for monitoring and control of facilities at the Changi DCS Plant.

In the past Keppel DHCS had Azbil’s Harmonas-DEO™ central monitoring and control systems installed in all of its DCS plants in Singapore with the support by Azbil Singapore Pte. Ltd. On the background that these systems have contributed to consistent operations and also maintaining the quality of cooling water of these plants, Keppel DHCS requested Azbil Singapore anew for plans to bring about energy savings in line with the road map Keppel DHCS had drawn up.

Azbil Singapore, in response, presented plans using approaches to achieve energysaving effects by adopting new technologies that enable optimal control of heat source while using existing facilities, such as chillers, cooling towers, and pumps. The presentation also included an ESCO*3 plan that guarantees energy-saving effects.

“In this scenario, we would not have to replace existing facilities with new ones, so we could hold down the initial investment. Moreover, Azbil would guarantee energy-saving effects for five years and a half thanks to the included ESCO plan. Therefore, the plan appeared to be very attractive to us in terms of minimizing risk. It sounded convincing for our parent company, Keppel Corporation, to give us an approval for the plan.” says Mr. Ng.

As a starter, Keppel DHCS implemented energy-saving measures to the Woodlands DCS plant, where upgrade of the existing facilities was kept to minimum by, for example, adding VSD (variable speed drive) units to them; and for the rest, a method of optimal control of all heat source facilities was adopted to improve the efficiency of their operations. Specifically, as an addition to the existing Harmonas-DEO system, a new utility optimization software package has been installed for optimal control of all heat source and utility facilities of the plant to meet the heat requirements of consumers and at the same time to minimize the overall electricity cost.

“At first we did not adopt for full automation of the plant operations in order to avoid risk. We were instructing operators to follow the guidance for optimal control of the facilities which is calculated by the optimization system, and there was always human intervention through the central monitoring and control system. However, as we were continuing to operate the plant with the optimization system, we have found the plant’s efficiency performance indicated by KPI*4 has increasingly been improved, which we considered to be proof of appropriate operations at all times. After that, we transited to full automation based on utility optimization calculation without human intervention. The optimal control program continuously calculates values and supports plant operations nonstop throughout the year, so we have no worries about achieving energy savings,” says Mr. Zaw.

Major functions of the utility optimization software package are:

1) Loading operational data from a chilled water plant through a monitoring and control system

2) Predicting the amount of heat load needed by the customer side based on historical demand and climate

3) Controlling chillers, cooling towers, and pumps to produce predicted heat optimally so that the overall energy consumption by these facilities is minimized

After Achieving Energy Savings Well Above Targets, Keppel Now Implementing Similar Measures to Other DCS Plants

Chilled water for air conditioning in the Biopolis business district is supplied from Keppel’s DCS plant.

As a result of implementation of energy-saving measures, the Woodlands DCS plant has achieved a large reduction in electricity consumption by 2.28 mil. kW/year, much above its target of about 1.85 mil. kW/year. The achievement rate is 123 % of the target, which is high.

Since the efforts on the Woodlands DCS plant yielded very favorable results, similar measures have subsequently been implemented to the DCS at the Changi and Biopolis plants, which achieved a reduction of electricity consumption, again much above their targets, by over 8 mil. kW/year in total.

“In addition to the eager support by Azbil Singapore in operating the systems, Azbil Corporation remotely monitors our Harmonas-DEO unit and optimization results from Japan to provide support system maintenance and will log on to address problems in case of emergency, so we can feel great peace of mind. The azbil Group has a strong technological background, so we could implement the measures with a feeling of trust,” says Mr. Zaw.

“Azbil has helped to train our engineers as well. During the process of the project, our engineers’ awareness and skills have been improved through discussions with staff from Azbil Singapore and Azbil Corporation in Japan,” says Mr. Keng.

Keppel DHCS will make further efforts to take on energy savings in areas other than DCS plants.

“Our company is engaged in operating chilled water plants for buildings also. We are thinking about constructing a system that enables monitoring and control of multiple heat source control systems operated by different buildings from Keppel Corporation or a special control center. It is an important theme for us to achieve energy savings in this effort as well. From that standpoint also, I think the azbil Group is a very important partner for us to work together in realizing energy savings,” says Mr. Ng.

* Harmonas-DEO trademarks of Azbil Corporation.

glossary

*1 District Heating and Cooling System (DHCS)

District heating and cooling system (DHCS) supplies chilled water, hot water, and steam from a centralized supply facility (plant) to a group of buildings in a district through its underground pipe network for the building’s space cooling and heating as well as for hot water supply. This system is also called district cooling system (DCS) in tropical and subtropical regions where heating is not necessary.

*2 BCA Green Mark Scheme

BCA Green Mark Scheme is a green building rating system to evaluate buildings’ energy efficiency and eco-friendliness operated by the Building & Construction Authority, an agency under the Ministry of National Development in Singapore. There are different levels of rating, including Standard, Gold, Gold plus, and Platinum.

*3 Energy Service COmpany (ESCO)

Energy service company (ESCO) provides comprehensive energy solutions for factories and buildings, and the saving is guaranteed by service providers.

*4 Key Performance Indicator (KPI)

Key performance indicator (KPI) is a quantifiable measurement that helps to show how well companies, business units, projects, or individuals are performing compared to their strategic goals and objectives.

Learn about the customer

Chief Executive Officer

General Manager

Technical Manager

Keppel DHCS Pte Ltd

Keppel DHCS Pte Ltd

- Location: 1 HarbourFront Avenue #05-05 Keppel Bay Tower Singapore 098632

- Founded: 1998

- Business scope: Development, construction, and operation of district heating and cooling systems and facilities.

This case study was published in the 2017 Vol.1 issue of the azbil Group's corporate magazine, azbil.