Idemitsu Kosan Co., Ltd.

Idemitsu Kosan, whose oil refining business provides energy for people’s everyday lives and economic activities, recently updated its plant information management system to meet the increasing threat of cyberattacks on important infrastructure. The new security-enhancing system, which uses the only communication standard recommended for Industry 4.0, gives company employees peace of mind as they analyze and utilize operational data.

Factories and Plants Oil Refining and Petrochemical Safety & Dependability Security Measures Industrial Automation Control and Monitoring Systems and Software

Products/Services Provided

An increasing risk of cyberattacks targeting important infrastructure

In the more than 100 years since its founding in 1911, Idemitsu Kosan Co., Ltd., has been supplying energy for daily living and economic activity. In April 2019, the company completed management integration with another company in the same industry. The newly integrated company will do business not only in areas connected with energy, like oil, electricity, and renewable energy, but also in areas connected with materials, like chemicals and organic electroluminescence. As a Japanese “energy co-creation company,” it is just taking its first steps.

For some years, the use of IT has been necessary in infrastructure-related industries, and Idemitsu is known for its leading initiatives in this area. For example, operational data that was once stored in individual control systems at oil refineries and other production sites all over the country is now collected by a plant information management system (PIMS).*1 The company analyzes its data using business intelligence (BI) tools,*2 and has taken steps to improve processes and productivity and to achieve energy efficiency ahead of other companies in the same industry.

“Especially in recent years, there is an increased threat of cyberattacks on infrastructure, such as targeting facilities that provide oil or electricity. Actually, some power generation, transmission, and distribution facilities overseas have been attacked, leading to power outages, and there are countless incidents resulting from cyberattacks. In light of such incidents, the Ministry of Economy, Trade and Industry has been urging businesses connected with important infrastructure in Japan to strengthen information security,” says Seiji Yoshii, manager of Idemitsu’s Information Systems (IS) Department.

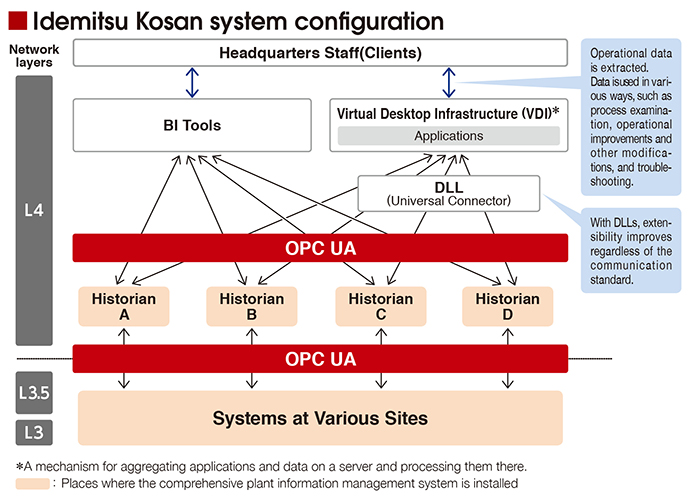

“Of course, this is an important topic for us, because our company is committed to providing a reliable energy supply for society. One problem we realized was that an interface called OPC Classic*3 was used to link data between site control systems, the PIMS, and the BI tools,” says Takahiro Ogata of the IS Department.

OPC Classic is widely used in manufacturing industries, etc., as a standard for exchanging process data and historical data between control systems and information systems. However, this interface requires that firewall ports on the periphery of the system be left wide open, which gives attackers a possible route for attack, and therefore it was a recognized security problem.

For that reason, Idemitsu Kosan decided to replace the aging PIMS and create a system compliant with OPC UA,*4 which is the new standard that supersedes OPC Classic. OPC UA is the only recommended communication standard for Industry 4.0, and since it can narrow down the ports that must be open for communication to one, it can greatly improve the security level compared to the old standard.

An enthusiasm for challenges and sense of mission

At Idemitsu Kosan, about 100 employees use BI tools to access and analyze operational data on the comprehensive plant information management system, which is useful for improving processes to achieve energy efficiency and higher productivity.

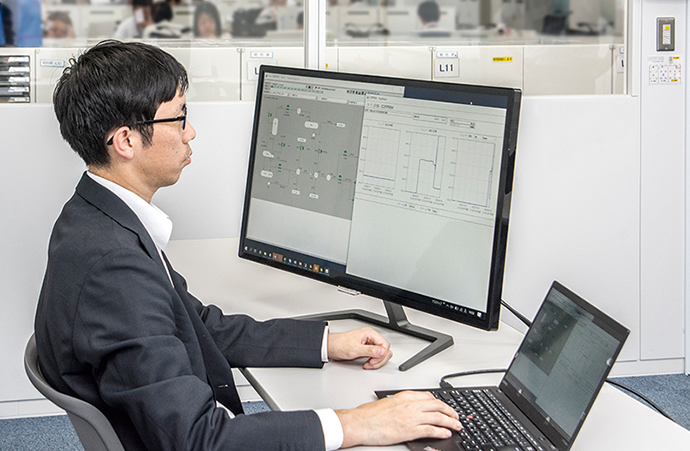

Idemitsu chose Azbil Corporation as its partner for updating the PIMS. Azbil offered to install its total plant information management system, which features long-term accumulation of plant operational data which can then be utilized by various departments throughout the company.

“Although we received proposals from multiple companies, including the vendor of our existing system, Azbil had a long track record of helping with the operation and maintenance of our PIMS, and its technical and support capabilities were widely recognized in our company. Above all, we were impressed by Azbil’s enthusiasm for boldly taking on the challenge of applying OPC UA, which is still rare in Japan, and by Azbil’s determination to get that job done, so we definitely wanted to have it as our partner,” says Mr. Yoshii.

Idemitsu selected Azbil at the end of 2017. System construction work began almost immediately afterward, and the new system went into operation in March 2019.

Idemitsu Kosan system configuration

Applications also standardized in anticipation of future systems

Idemitsu has long built and operated various applications that access the PIMS in addition to BI tools. In the recent upgrade, the processing of functions related to the acquisition of data stored in the PIMS was standardized with a common Dynamic Link Library (DLL).*5

“This standardization allows applications to be PIMS-independent, so even if the PIMS is replaced with another package in the future, we will be able to make a smooth transition, without modifying the individual applications, simply by changing the DLL,” explains Satoshi Takano of the IS Department.

With the upgrading of the PIMS by a comprehensive plant information management system compliant with OPC UA, Idemitsu raised the level of security for its analysis and utilization of operational data. There is now greater peace of mind with regard to cyberattacks. “When we use BI tools and applications, we can now extract and display a half year’s worth of operational data, which used to take about one and a half minutes, in only 10 seconds. That is one result of transitioning to the new system that improves user convenience,” says Mr. Ogata.

“Our company, which relaunched as a new integrated company, will continue to reorganize production sites and systems using the latest digital technology, including the Internet of Things (IoT), big data, and artificial intelligence (AI), and we would like to further develop the measures that have been taken in order to further integrate IT and operational technology (OT). We have high expectations for Azbil to continue proposing new technology and solutions that contribute to our efforts,” says Mr. Yoshii.

Windows is a registered trademark or trademark of Microsoft Corporation in the United States and other countries.

glossary

*1 Plant information management system (PIMS)

A system for collecting and storing process data and manufacturing data from various monitoring and control systems in plants and factories, and for visualizing and analyzing the operation and manufacturing status of the manufacturing equipment.

*2 Business intelligence (BI)

Methods and software that visualize, process, and analyze business data from various corporate systems and utilize it for business and management decision-making.

*3 Open Platform Communications (OPC) Classic

A standard for exchanging process data, alarms, historical data, etc., based on the distributed component object model (COM/DCOM) of Microsoft Windows. Its original name was OPC data access (OPC DA), but it is now called OPC Classic to distinguish it from the newer OPC UA.

*4 Open Platform Communications Unified Architecture (OPC UA)

A standard for data exchange that inherits the interoperability of OPC Classic and improves it by enabling data exchange between different operating systems and multi-vendor products using a service-oriented architecture (SOA), while at the same time improving reliability and security.

*5 Dynamic Link Library (DLL)

A software library that uses dynamic linking. In a DLL, general-purpose functions used by multiple programs are modularized for sharing by the executable files that read the link.

Learn about the customer

Manager

System Development Section 2

Information Systems Department

(registered information security specialist)

System Development Section 2

Information Systems Department

System Planning Section

Information Systems Department

Idemitsu Kosan Co., Ltd.

Idemitsu Kosan Co., Ltd.

- Address: 2-1, Otemachi 1 chome, Chiyoda-ku, Tokyo

- Founded: March 30, 1940

- Business: Manufacture and sale of petroleum products, petrochemical products, and electronic materials

This article was published in July 2021.