HOME > Products > Products and Services for Factories and Plants > Support and Training > Life Cycle Support > Valve Diagnostics Service > Results Effect > Avoid Sudden Equipment Shutdown

Avoid Sudden Equipment Shutdown

Without diagnosis,

an unnoticed problem might suddenly escalate into trouble...

Trust Azbil’s Valve Diagnostics Service to help you implement condition-based maintenance (CBM).

A diagnosis helped to find a problem in a control valve

that would not have been repaired under time-based maintenance (TBM)

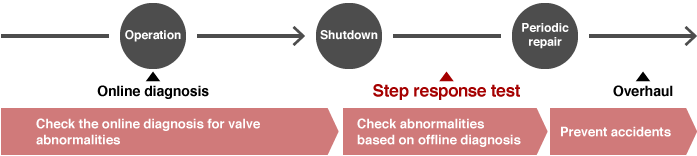

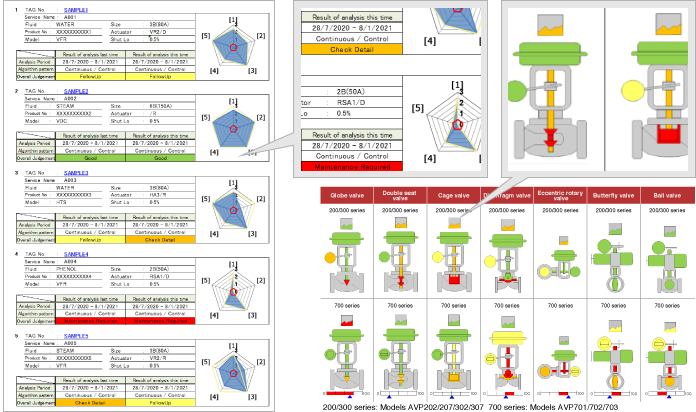

Online data-based diagnosis by our Valve Diagnostics Service during control valve operation detected an abnormality that would not have been repaired under TBM. The valve received Maintenance required and Check thoroughly evaluations.

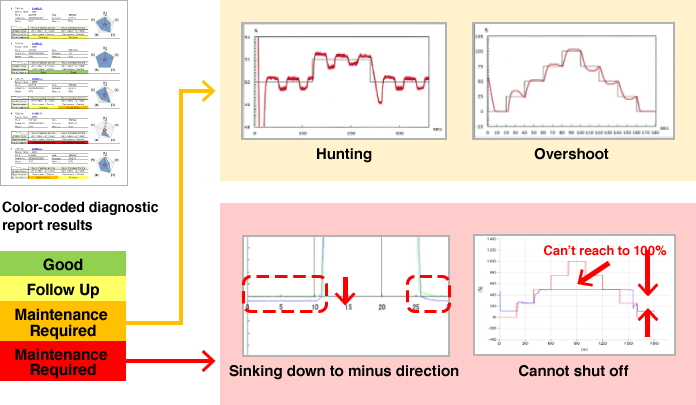

A step response test revealed a problem that was unnoticed during operation

After shutdown, offline diagnosis revealed that there was something abnormal about the valve, so it was added to the overhaul inspection list.

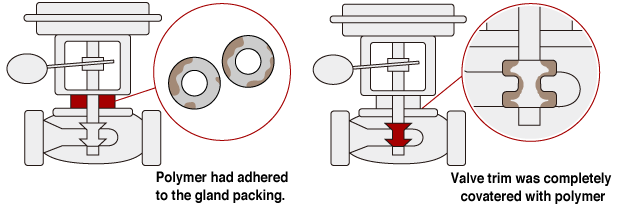

The overhaul inspection confirmed the diagnosis.

Contact information for inquiries about the Valve Diagnostics Service

- Valve Diagnostics Service

- Diagnosis Overview

- Types of diagnosis

- Service Menu

- Dx Valve Basic Service plus

- Diagnostic Tools

- Diagnosed Cases

- Use Cases, Customers, and Results

- Avoid Sudden Equipment Shutdown

- Optimizing Maintenance Plans (to TBM + CBM)

- Faster Equipment Startup after Periodic Maintenance

- Diagnostic possibilities with the Smart Valve Positioners 700 Series

- FAQ

- Introduction of our capability for factories and plants

- Maintenance Support

- Life Cycle Support

- Energy-Saving Program for Factories and Plants

- Equipment Diagnosis Support for Factories and Plants

- Advanced Automation Company Training Center

Related Information