Mass Flow Rate

The mass (roughly speaking, the weight) of a fluid that flows per unit time. The value is expressed in units such as kg/min. Even in the case of gases, whose volume changes with the temperature and pressure, the amount of flow can be expressed consistently by the mass flow rate.

- Volumetric flow rate or mass flow rate? It all depends on what you are measuring

- Flow rate measured by a force acting on the fluid, or by molecular weight

- With improved mass flow meters, better utilization of measured data

Volumetric flow rate or mass flow rate? It all depends on what you are measuring

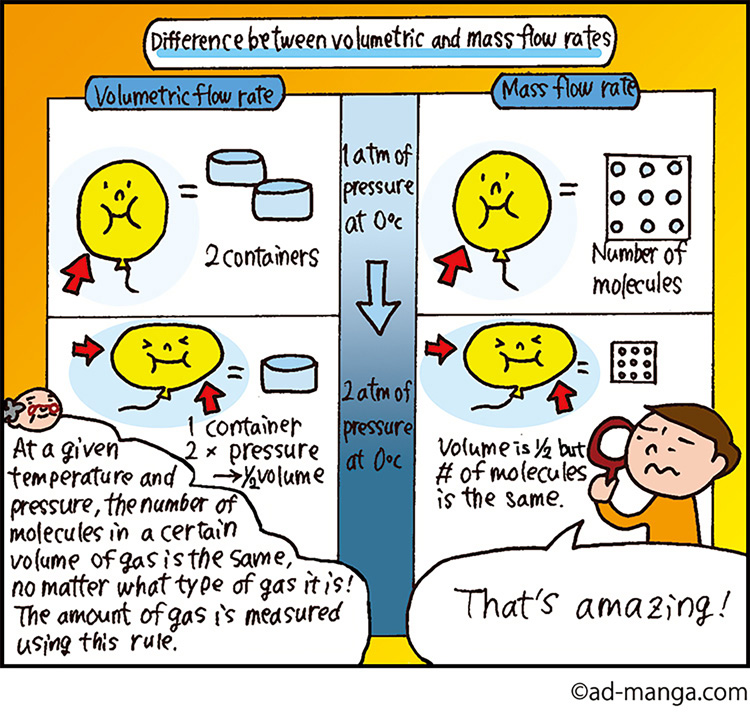

To check water, gas, or fuel usage, the amount of flow within a fixed amount of time is measured and the bill is calculated based on the amount used. Volumetric flow rate expresses the amount of fluid (a liquid or gas) in a unit of volume such as L/min, while mass flow rate expresses the amount in a unit of mass such as g/min.

When a gas is measured, we must remember that the volume of gases changes depending on the temperature and pressure. For example, if 10 liters of gas is flowing by every minute, the volumetric flow rate is 10 L/min, but if the pressure doubles, the gas will be compressed into only half of the volume. At the same volumetric flow rate of 10 L/min, the mass (the real amount of gas) will be double. Mass flow meters measure the amount of molecules in a gas (= the mass), so their measurements are not affected by temperature or pressure. Since the volume of liquids is less affected by temperature or pressure, liquids are measured by volumetric flow rate, but gases are often measured by mass flow rate.

Flow rate measured by a force acting on the fluid, or by molecular weight

Mass flow meters can be roughly divided into two types. One type directly measures some physical property related to mass, while the other indirectly calculates the mass by correcting the volumetric flow rate.

There are two direct measurement approaches, Coriolis and thermal. The choice between the two depends on the physical property being measured.

A Coriolis flow meter uses a measurement method based on the operation of the Coriolis force, which is an inertial force that works to change the velocity of an object moving on a rotating body. When a fluid flows through vibrating U-shaped tubes, the frequency of vibration changes due to bending of the tubes by the Coriolis effect. The flow rate is measured based on the change.

A different direct approach is used by thermal flow meters, which measure the flow rate by measuring the molecular weight of the gas. The weight of the molecules in a fixed volume of gas and the thermal conductivity rate (heat transfer ability) per molecule are fixed values. Since the weight of the molecules in the gas does not change with temperature or pressure, the mass flow rate of the gas can be measured by heating it and measuring how much heat is transferred or how much heat is lost. Measurement by thermal mass flow meters has been achieved in recent years using a tiny, few-millimeter-square sensor chip.

Thermal mass flow meters are used to control the flow rate of gases in a variety of settings, including automobile engines, semiconductor manufacturing equipment, glass processing manufacturing, boilers, and fuel cells.

In contrast to the approaches described above, indirect approaches measure the volumetric flow rate and then correct it according to the temperature and pressure in order to calculate the mass flow rate. This method requires a temperature sensor and a pressure sensor in addition to a volumetric flowmeter.

With improved mass flow meters, better utilization of measured data

In the future, improved flowmeters using each approach will no doubt be developed. How the measured data can be used is also an important question to be answered.

Also, if flow rate can be measured without touching the fluid, it will be a major breakthrough. Although it is already possible to measure liquid flow rate from the outside of a tube using ultrasonic waves, new technology using an optical approach, for example, may change the value of the flowmeter itself.