Using the IoT to Create New Value in Manufacturing

The Japanese manufacturing industry has seen an increasing demand for safety, dependability, reliable operation, and further productivity improvement because of changes in the business environment, such as aging plants and a labor force that is decreasing due to the low birthrate and aging population. Azbil has long contributed to customers’ production sites with its measurement and control technology and its pioneering initiatives for “smart industrial safety.” Now Azbil is undertaking new initiatives aiming for “a new dimension of productivity” that boosts manufacturers’ businesses more comprehensively.

- Manufacturing industry change generates a greater need for safety, dependability, and productivity

- With smart industrial safety, stable operation follows

- Advancing a new vision for achieving a new dimension of productivity

Manufacturing industry change generates a greater need for safety, dependability, and productivity

In the Japanese manufacturing industry, the importance of safety, dependability, reliable operation, and improved productivity has received much attention. There are several reasons for this, one of which is aging plants. There are quite a few in Japan that have been operating for over 50 years. Under these circumstances, many of the experienced operators who assisted in production during that time have reached retirement age, and in some cases their knowledge and expertise are being lost. Because the working population is decreasing due to a declining birthrate—a situation that will accelerate in the future—plant operation must be handled by a smaller number of employees.

Dealing with this challenge is increasingly important, especially for chemical plants. Based on the azbil Group philosophy of “human-centered automation,” the Advanced Automation Company (AAC) is developing products and services to further improve productivity and quality. These efforts include the area called smart industrial safety, which uses advanced technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI).

A new dimension of productivity

With smart industrial safety, stable operation follows

Azbil offers a variety of solutions for smart industrial safety at plants. By using smart valve positioners and simple valve diagnostic equipment, we monitor the operating status of valves and their diagnostic parameters in order to catch valve anomalies at an early stage. In addition, we provide products that collect operational data in real time. Together with these products, we offer services in which our professional engineers analyze the collected data in order to recommend, for example, which valve should be replaced first. The result is more efficient, optimized maintenance.

One of our latest products uses technology such as machine learning to analyze large amounts of data (big data) that is collected from each piece of equipment in a facility, so that unusual equipment behavior, which is an advance warning sign of problems, can be detected in real time. This is known as our online anomaly monitoring system. Another product, which provides advanced critical trend monitoring for safety, predicts future fluctuations based on past data, and issues alarms to prevent future trouble.

Azbil has a proven track record of delivering products and services for smart industrial safety to a large number of customers in Japan. Its leadership in this area has received high praise from all quarters. According to a report released by Japan’s Ministry of Economy, Trade and Industry in April 2017, which examined smart industrial safety initiatives at 25 leading companies, Azbil is involved in the initiatives of seven of those companies. An explanation of our smart industrial safety using the IoT was given at the fourth Future Investment Meeting*1, which was held at the Prime Minister’s official residence on January 27, 2017, and at a panel discussion at the Thailand 4.0*2 symposium held in Bangkok, Thailand, on September 12, 2017. Our initiatives attracted a great deal of attention.

Advancing a new vision for achieving a new dimension of productivity

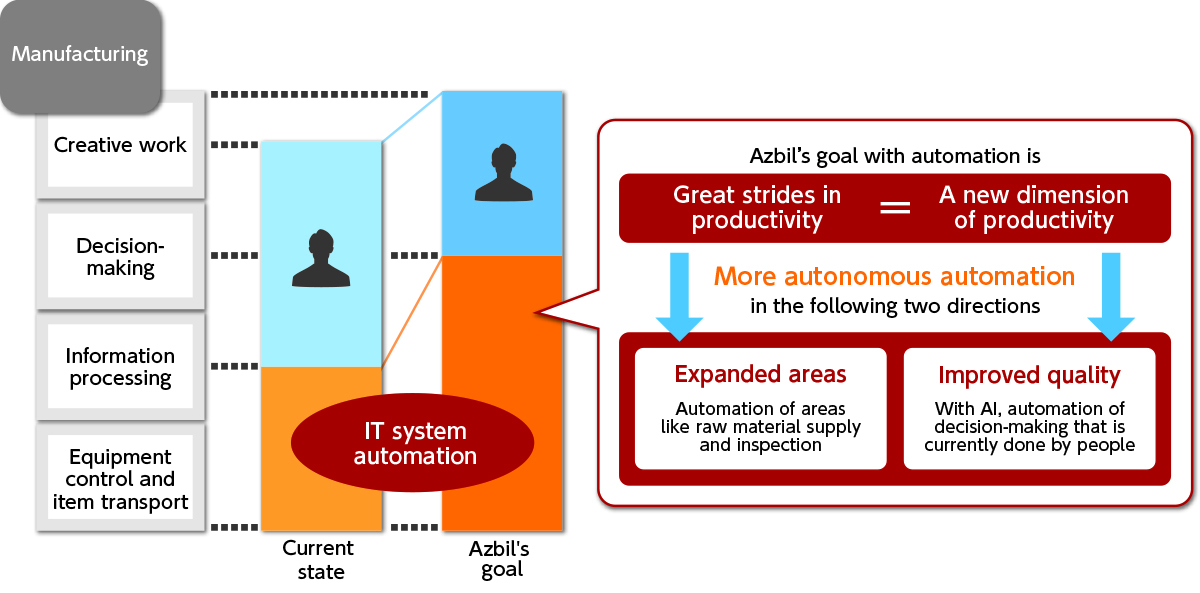

Many factories and plants have already introduced automation into their production lines. Therefore, Azbil is aiming at a new dimension of productivity that makes factories and plants more productive than ever, and is much more than a small step forward from previous improvements.

Conventional automation plays a role in controlling equipment and transporting items. In addition to these conventional functions, Azbil believes that it is also necessary to provide products and services fulfilling the new roles of advanced information processing and decision-making, and we are now developing such automation products and services. This advanced automation will provide the manufacturing industry with an environment where customers can focus more on creative business activities, which is something only human beings can do, including accelerated product development, service improvement, and globalization.

Azbil is the right company to develop this vision because it is in the business of contributing to factory operations based on the azbil Group philosophy of “creating value together with customers at their sites” by providing measurement and control for particular equipment or lines, optimizing overall production planning and operation by mathematical programming and multivariable model predictive control, and developing applications and providing operational assistance.

To achieve a new dimension of productivity, it is essential to develop new technology and also to sense and predict the current and future needs of customers, so we are making efforts from a variety of perspectives. As an example, we continually hold IoT technology exchange meetings with customers who are undertaking advanced production initiatives. These kinds of meetings are places where we can understand customers’ needs and problems, which is that necessary step in achieving that new dimension of productivity. Topics are not limited to production facilities, but also include management issues, which must be considered from a broad perspective. We create this type of opportunity so that we can use the resulting findings to create new products and services.

Azbil intends to continue to make contributions to the manufacturing industry by utilizing the measurement and control technology and expertise we have cultivated over many years, and to achieve a new dimension of productivity in line with the Group philosophy of “human-centered automation.”

*1 Future Investment Meeting

This meeting combines an industrial competitiveness meeting with a public-private dialogue for future investment, and serves as a “control tower” for a growth strategy that promotes investment by public-private partnership in areas where investment will help future growth, expand future investment, and accelerate structural reform. The chairman of the meeting is the Prime Minister of Japan.

*2 Thailand 4.0

An economic model created by the Thai government. Its aim is to create, within 20 years, an economy and society that continuously creates added value, with keywords such as innovation, productivity, and trade in services.

This article was published on April 1, 2019.