Autonomy

For a given goal, a system proactively creates the optimal execution plan and then carries out the tasks while automatically dealing with any obstacles that may arise. This approach aims to achieve goals by implementing the Plan-Do-Check-Act (PDCA) cycle, analyzing the results and providing feedback, without human intervention.

- Achieving goals without human intervention based on automation technology

- Automatically running the PDCA cycle to maximize performance

- Autonomy holds the key to resolving increasingly complex social issues

Achieving goals without human intervention based on automation technology

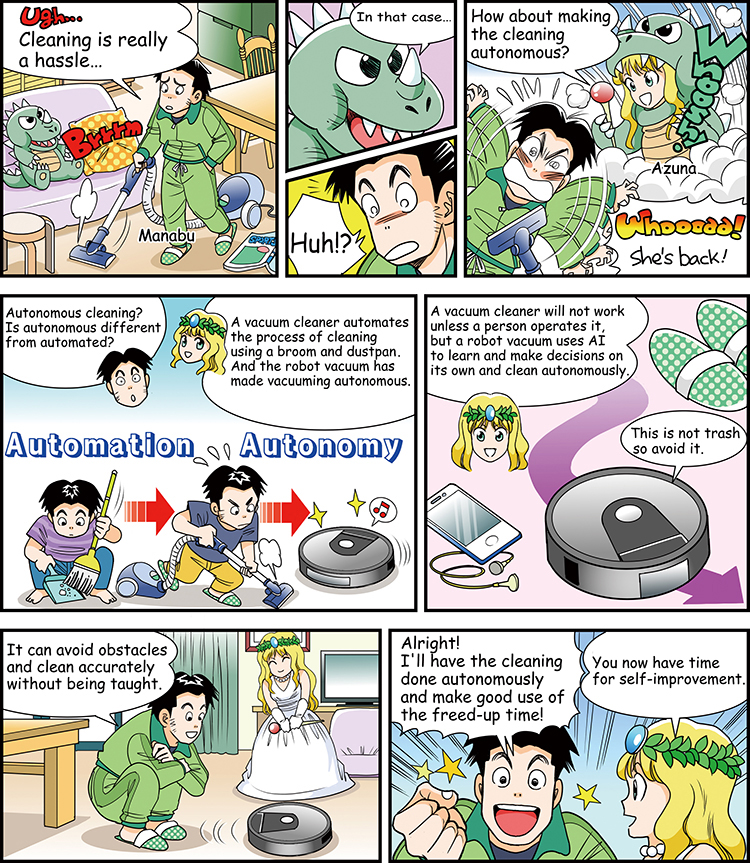

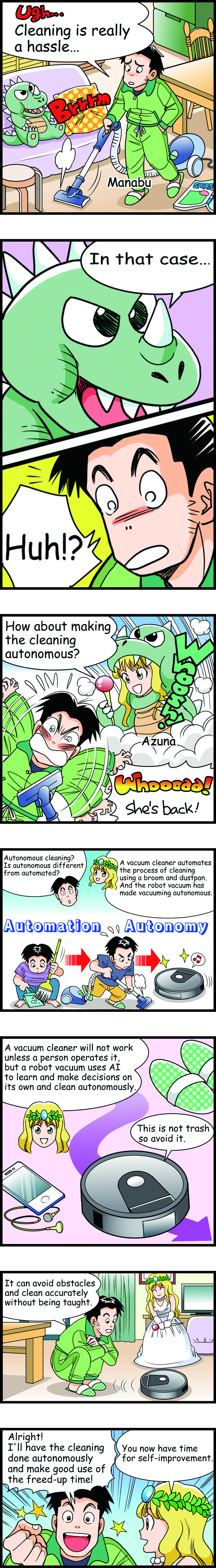

Digital Transformation (DX), which aims to transform people's lives for the better by integrating advanced digital technologies into society, has been accelerating in recent years. In this context, autonomy using AI and IoT is attracting increasing attention. It may sound similar to automation, but while automation involves a machine reproducing a series of predetermined manual tasks, autonomy aims for the system not only to perform defined actions but also to respond to situational changes and to make decisions on its own.

For example, cleaning with a broom and dustpan is a manual task, whereas a vacuum cleaner is an automated version of the broom and dustpan, but it still requires human interaction to complete the task. In contrast, a robot vacuum can recognize the entire room's layout and obstacles on its own, and then effectively complete its tasks without human operation. This is autonomy.

In addition, regarding self-driving automobiles that are gradually being introduced into the market, having no automated driving functions is defined as level 0, with the degree of automation being identified by levels 1-5.

Levels 1 to 3 include features such as collision damage mitigation, inter-vehicle distance control, and autonomous driving under certain conditions, with the driver playing the principal role in driving operations. On the other hand, at levels 4 and 5, driving operations are mainly performed by the car itself, and it is said that even the driver's seat is no longer necessary. Thus, it can be said that up to level 3 is the realm of automation, and autonomy is only achieved at levels 4 and 5.

In this way, autonomy is an approach to completing tasks through mechanization and automation, in a way that minimizes human intervention. It is a concept common to everyday objects, such as robot vacuums, as well as to buildings and production fields. The main difference between autonomy and automation is that in autonomy the system is capableof intelligent human behavior: recognizing situations, analyzing conditions, and carrying out tasks in the most optimal way.

Automatically running the PDCA cycle to maximize performance

With the goal of freeing people from heavy labor and increasing productivity, these technologies have developed into automation systems that mechanize and automate labor-intensive production lines, in areas such as adjustment control, which brings measured values closer to target values, and sequence control, which operates machines in a set order. However, in traditional automation even though prescribed actions could be performed as defined, human intervention was essential in complex situations as well as when dealing with problems and unforeseen circumstances. However, recent advances in digital technologies such as AI and IoT have made it possible for systems to emulate intelligent human behavior, collecting data in real time, learning from past data, and analyzing situations based on that data. Furthermore, with the development of industry and the economy, the world is shifting from a consumer society to a sustainable one, and towards an era in which well-being is given more importance than material wealth. As a result, the demands on manufacturing sites are becoming more sophisticated and complex. It is not enough to simply increase productivity; we also need to address social issues such as environmental problems and a shrinking labor force. Autonomy is the concept of using digital technology to automate control and management, or what is commonly known as PDCA, which has traditionally been performed by humans.

Autonomy holds the key to resolving increasingly complex social issues

The greatest benefit of autonomy in manufacturing is that it enables factories and plants to continuously maximize their potential. AI comprehensively analyzes various factors such as product volume, manufacturing costs, and energy consumption to implement the best production plan. It will also be possible to proactively predict and detect abnormalities in product quality and production equipment that affect it, as well as to identify other factors that affect product quality and implement corrective measures. Improving the efficiency of production activities will lead to increased profits and a stable supply of high-quality products, as well as contributing to solving social issues such as reducing greenhouse gas (GHG)*1emissions to achieve carbon neutrality and promoting digital transformation. Furthermore, minimizing human intervention can lead to reductions in human resources and errors. As many tasks are digitized, it also will become possible to work in diverse ways without constraints such as time, location, gender, etc.

Over time, the goals of automation are also changing in ways that contribute to solving social issues. In the future, the entire production process will be automated based on the automation of each step, allowing humans to focus on more creative tasks that only they can perform, such as the development of renewable energy and new technologies. While this assumes further evolution in digital technology and other areas, there is no doubt that autonomy is one of the keys to realizing a sustainable society.

*1:Greenhouse gases (GHGs)

A general term for gases in the atmosphere that cause a “greenhouse effect” by absorbing part of the infrared radiation emitted from the Earth’s surface.