Using Advanced Technology to Meet the Challenge of “New Automation”

Azbil is applying advanced sensing technology, AI, and other technology to bolster its product development and provide new solutions that promote safety, productivity, and value enhancement at manufacturing sites

Azbil’s advanced automation (AA) business provides a wide variety of solutions for factories, plants, and other manufacturing sites. By strengthening our ability to develop products and systems that take advantage of advanced technology like high-precision sensors, IoT, AI, big data, and cloud computing, we aim to “create new automation” in order to grow and develop.

Yoshimitsu Hojo

Executive Director and

Managing Executive Officer

President of the

Advanced Automation Company

Azbil Corporation

- Utilizing advanced sensing technology and AI to promote smart manufacturing

- “New automation” becomes a source of AA business growth

- Aiming to be an industry leader with technological capabilities and strengths cultivated over many years

Utilizing advanced sensing technology and AI to promote smart manufacturing

Azbil Corporation’s AA business provides comprehensive solutions and services related to automation for production sites such as factories and plants—from operation monitoring systems to valves, controllers, and other field devices.

We serve a wide range of business areas, including large-scale petroleum, chemical, and steel plants; electrical/electronic, semiconductor, automobile, food, and pharmaceutical factories; and infrastructure facilities such as power plants, gas processing plants, water purification plants, and waste incineration plants.

In these diverse markets, the required solutions and the provided products and services can vary widely. Azbil has a proven track record of providing products, systems, and maintenance services that help customers to solve problems at production sites, in areas like production, quality control, energy efficiency, safety, and the environment, based on measurement and control technologies that have been cultivated over many years.

In recent years, our focus has been on the development of products and services that use a higher level of information processing and decision making to support automation. An example is Azbil’s approach to “smart safety” at plants.

Currently, at customers’ sites, skilled operators who have been responsible for handling maintenance are retiring and the labor shortage is becoming more serious, with the workforce expected to decline into the foreseeable future. Furthermore, many plants in Japan have aging facilities, heightening the risk of serious accidents. To improve this situation, we are making industrial safety smarter (= smart safety) utilizing the Internet of Things (IoT) and new technology like big data and artificial intelligence (AI) in order to improve site safety, compensate for the labor shortage, and strengthen the international competitiveness of our customers. This kind of initiative is being promoted in Japan through public-private partnerships.

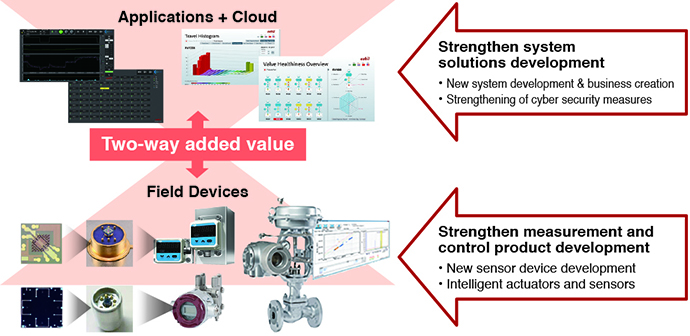

System configuration for the IoT era, and the planned methods of improving azbil Group product capabilities

“New automation” becomes a source of AA business growth

For smart safety, Azbil defines “three eyes” to help customers improve site safety and productivity. The “first eye” includes the factory’s or plant’s system for operation monitoring, as well as staff patrols.

The “second eye” is the implementation of optimal maintenance based on equipment diagnosis by high-performance sensors. As an example, the positioner that controls a valve can be equipped with a highly advanced sensor that converts the operating condition of the valve into data. Accumulating, analyzing, and “visualizing” this kind of detailed data with Azbil’s control valve maintenance support system makes it possible to detect valve deterioration and abnormalities without stopping the operation of the equipment for inspections. Since it is now possible to conduct “health checkups” for the equipment, safety and productivity at production sites can be improved and the efficiency of inspections can be increased.

The “third eye” is detecting symptoms of anomalies and predicting future changes using AI and big data. Like a skilled operator who has learned to make good judgments from past experience, Azbil’s online anomaly monitoring system learns to recognize various operational patterns from big data, enabling it to detect signs of trouble in the behavior of facilities, equipment, and processes at an early stage and sound the alarm. Since our AI monitoring systems went on the market in 2015, over 1,000 have been sold.

Nowadays, as technological innovation progresses, new forms of automation are being born in each area of the market where the AA business is involved. Also, each customer has a wide variety of automation needs. Developing new automation areas that provide new value to customers is becoming a source of AA business growth.

For example, quantities that previously could not be measured accurately are now being measured by advanced technology. Azbil has developed the model F7M micro flow rate liquid flowmeter, which uses a thermal method to accurately measure the instantaneous flow rate of very small amounts of liquid. The F7M can handle tasks that were difficult by conventional methods, such as determining the instantaneous flow rate and total flow volume of minute liquid flow rates of 0.1 to 50 mL/min. By using a sensor equipped with MEMS*1 technology, an Azbil specialty, and applying a new production technology for bonding the sensor to a tube—which was said to be extremely difficult to do—Azbil was a frontrunner worldwide when it released this product. Introduced for use in industrial equipment, semiconductor manufacturing equipment, and pharmaceutical manufacturing, the flowmeter is providing new value and solutions for customers.

Similarly, our business strategy for the measurement equipment, field equipment, and operation monitoring systems that have been at the center of the AA business so far is to enhance development capabilities in two ways.

The first is to strengthen the development of field devices through the use of new sensors equipped with the aforementioned MEMS technology, and the combination of these devices into networks.

The second way is to strengthen the development of system solutions that will lead the way into the IoT era by fusing applications and cloud computing, as in the online anomaly monitoring system described above. By increasing the added value of products and services in both ways, we intend to create new business models and expand the “new automation” market.

Aiming to be an industry leader with technological capabilities and strengths cultivated over many years

As the times and technologies change, we face a greater variety of competitors, but I believe that Azbil has three major strengths.

One is our technology and knowledge related to measurement and control automation, which we have cultivated at numerous sites throughout many years. For example, even if you can analyze data using AI, if you do not have the knowledge and experience to know what kind of field data needs to be stored and how different types of data relate to each other, you will not be able to provide customers with optimal solutions.

Our second strength is related to the words “performance,” “quality,” and “safety.” In the field of measurement and control automation, where extremely high performance, quality, and safety are required, Azbil has accumulated the technology, systems, and know-how to provide those necessities all throughout the development process—in design, inspection, verification, etc.

The third strength is our long-term supply system for products and services. Equipment and systems installed at customers’ production sites will operate for 15 to 25 years or more. To ensure continuing quality and safety, Azbil supplies and maintains products and parts for a long time. Azbil aims to be a leading automation company by further enhancing these strengths, which are our advantages over the competitors.

At the same time, in the global market, we are developing a business based on “solutions close to the field,” especially in China and Southeast Asia, but also in South Korea, India, Saudi Arabia, Europe, and the U.S. Overseas sales account for approximately 25% of total AA business sales, and they are increasing every year. In overseas markets, too, Azbil’s products are highly regarded for their good performance, long-term reliability, consistent measurements, lack of breakdowns, and good servicing system, especially in China and Southeast Asia, where industries are continuing to expand and business opportunities are increasing.

Going forward, in the AA business, we will strive to develop solutions and provide products and services as partners who help to enhance and increase value for our customers inside and outside Japan, based on the philosophy of “human-centered automation.”

*1 MEMS (microelectromechanical system)

A microscopic electrical and mechanical system made using semiconductor manufacturing processes. Azbil began focusing on MEMS technology in the early 1980s, when it started developing sensors for industrial applications. Currently, MEMS chips are incorporated in many Azbil products, including humidity sensors, pressure sensors, and magnetic sensors.

This article was published on January 1, 2020.