Azbil Receives 2025 SICE Technology and New Product Development Awards

TOKYO, Oct 27, 2025: Azbil Corporation (Tokyo Stock Exchange code 6845) announced that it has received one Technology Award and two New Product Development Awards from the Society of Instrument and Control Engineers (SICE) for fiscal year 2025.

SICE is a key academic society that engages in research; collaboration with industry, government, and universities; and information dissemination in the areas of measurement, control, and systems. The Technology Award is given for technical achievements that have created or implemented new methods, devices, products, etc., and have had a remarkable effect. The New Product Development Award recognizes new and original products that have contributed to the development of an industry field.

Technology Award

“No-Latency Interleaved Delta-Sigma ADC for Multiple-Sensor Interfacing Circuits”

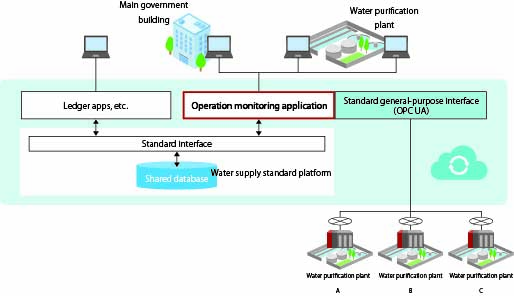

Circuit diagram (top) and timing diagram (bottom) of a newly designed interleaved delta-sigma modulator

ADC is a device that converts analog signals such as sound and temperature into digital signals. This conversion allows electronic devices such as computers and smartphones to process analog information as digital data.

With conventional AD converters, when collecting signals from multiple sensors, there is a time delay (latency) between the input paths (channels), which causes a loss of data correlation during correction calculations. Furthermore, configurations using multiple components cause increases in power consumption and costs, and errors between devices, making it difficult to achieve high-precision measurements.

This technology significantly reduces inter-channel latency through a unique time-division*1 sampling technique. By simultaneously maintaining correlation between sensor data and reducing inter-channel errors, it enables low-power consumption and high-precision measurements.

These advances have resulted in a groundbreaking innovation that simultaneously satisfies the requirements for high precision, low power consumption, and simultaneous multi-channel measurement required of measuring instruments. In the future, it is expected that this technology will be applied in a wide range of fields, including IoT devices and next-generation measurement systems. Its innovativeness and social significance were highly praised, leading to the Technology Award.

Reference site

Development of an interleaved delta-sigma A/D converter optimized for multi-sensors

New Product Development Award

“Sapphire Capacitance Diaphragm Gauge Model V8”

Sapphire capacitance diaphragm gauge

Semiconductor manufacturing processes are evolving every day, and vacuum gauges, which are essential for maintaining a vacuum environment, are now required to have improved resistance to deposition*2, be able to withstand high-temperature environments, and have fast response times. To meet these needs, we have developed the new diaphragm vacuum gauge model V8, a significant evolution of the conventional sapphire vacuum gauge model SPG.

The unique structure, which makes full use of MEMS*3 processing technology, significantly reduces deterioration of characteristics due to the accumulation (deposition) of process by-products on the diaphragm, achieving stable, high-precision measurement. Furthermore, the structure in which the gauge head and control unit are separated (separate type on the right in the photo) makes it possible to measure high-temperature gases up to 250°C. In addition, innovations in measurement circuit technology have enabled a high-speed response of 1 ms, making it compatible with next-generation semiconductor processes such as ALD*4 and ALE*5.

This product won the Good Design Award and the Japan Vacuum Industry Association Innovation Award in 2023. The system has been highly praised by the world’s leading semiconductor manufacturing equipment manufacturers, who commented that it “enables stable measurements without being affected by deposition,” “enables highly reliable measurements even with high-temperature gases,” and “meets the high-speed measurement requirements of new processes.”

Product website

Sapphire Capacitance Diaphragm Gauge Model V8C/V8S | Pressure Sensors/Vacuum Gauges | Azbil Corporation

New Product Development Award

“Harmonas-DEO™ Operation Monitoring Application Compatible with Water Supply Standard Platform”

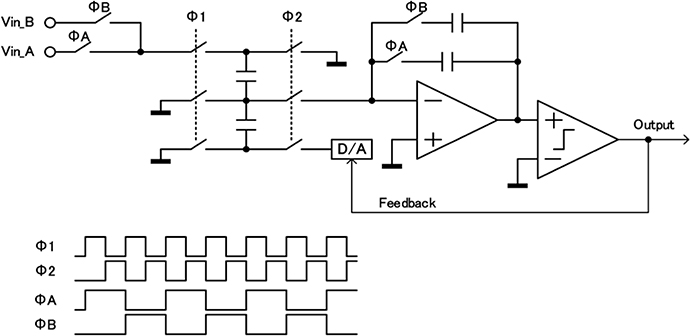

This product is a cloud application that is compatible with the Water Supply Standard Platform, which the Japanese government is promoting as a common platform for standardizing information systems and data integration in the water supply industry.

For communication with field devices, we adopted the OPC Unified Architecture (OPC UA*6), which is widely used in the measurement and control market. This application has a built-in monitoring operation database (OPDB), which allows for monitoring operability equivalent to that of a conventional on-premises system, even via the cloud. In addition, by linking the OPDB with the common database within the water supply standard platform, it has become possible to utilize information with various applications provided by other companies.

This product has been introduced as an off-site monitoring system for waterworks facilities and has received high praise in actual operation.

Guided by the azbil Group’s philosophy of “human-centered automation,” Azbil Corporation is committed to contributing “in series” to the achievement of a sustainable society, to secure its own sustainable growth, and to help solve problems faced by society by developing products and new technology that realize safety, comfort, and fulfillment to customers.

About Azbil Corporation

Azbil Corporation, formerly known as Yamatake Corporation, is a leading company in building and industrial automation, using its measurement and control technologies to provide customers with high value-added solutions to make their operations more efficient and sustainable. Founded in 1906, The Azbil Group consists of 30 companies and operates in 16 countries, providing cutting-edge solutions and services to meet the diverse needs of its global customers. As of March 31, 2025, Azbil employed about 9,000 people worldwide and generated JPY 300.4 billion in revenue. To learn more about Azbil Corporation and its solutions, please visit Azbil’s website at https://www.azbil.com.

*1 Time division: Dividing a specific time into parts and performing different processing on each part.

*2 Deposition: In semiconductor manufacturing, this refers to a film formation process that produces a thin film.

*3 MEMS (microelectromechanical systems): Various devices or systems such as sensors that incorporate microscopic electrical and mechanical elements on one chip.

*4 Atomic Layer Deposition Method. A method of forming flat, dense, thin films by controlling film thickness at the atomic layer level.

*5 Atomic Layer Etching. In semiconductor manufacturing, this is cutting-edge dry etching technology that removes the thin film on the wafer surface with great precision, at the atomic level.

*6 Open Platform Communications Unified Architecture. A standard for data exchange that inherits the interoperability of the conventional standard and improves it by enabling data exchange between different operating systems and multi-vendor products using a service-oriented architecture (SOA), while at the same time improving reliability and security.

* Harmonas-DEO is a trademark of Azbil Corporation.

* Posted information is accurate as of the date of announcement.