Enhancing Global Production and Expanding the Functions of Production Bases

Rolling out advanced production technology from the mother factory to bases in Japan and abroad

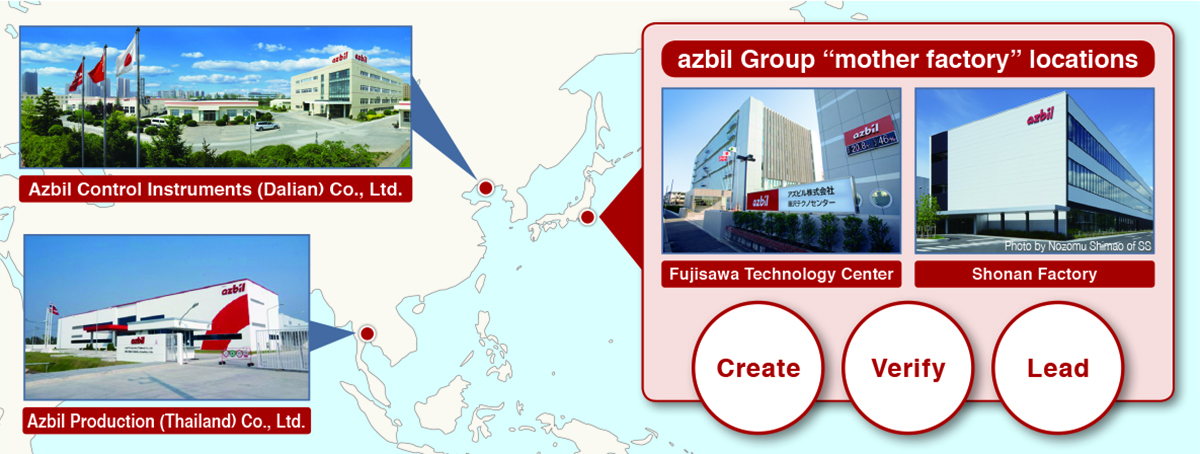

The azbil Group, with its focus on global business development, is working to develop and strengthen production bases worldwide. At the same time, by positioning Shonan Factory and Fujisawa Technology Center as a “mother factory” for global production, the azbil Group is innovating and standardizing production processes, with emphasis on developing and automating new production technology that incorporates the latest technological advances, in order to establish a system that provides customers with unique azbil Group value in a timely and high-quality manner.

- Establishing a production system to support global business development

- Taking on the challenge of automating high-mix low-volume production that creates high-value-added products

- Azbil’s mother factory leads in production, logistics, procurement, and human resource development

- Contributing to a sustainable society and continuous company growth

Establishing a production system to support global business development

The azbil Group, with the aim of delivering the value that Azbil Corporation has cultivated in Japan—in terms of technology, products, and services—to a wider range of customers in overseas markets, has been making full-scale efforts to expand its business globally. Accordingly, the Group is gradually developing a global production system and working to make it competitive.

With regard to overseas production bases, Azbil Control Instruments (Dalian) Co., Ltd. (the former Dalian Yamatake Control Instruments Co., Ltd.) was established in Liaoning Province, China, in March of 1994, and began producing air conditioning valves and mechanical switches for the building market. In the past few years, that has been expanded to include industrial valves, valve positioners, and differential pressure / pressure transmitters for the plant and factory markets. Also, in February 2013, Azbil Production (Thailand) Co., Ltd., was founded as a new production base in Southeast Asia. It produces mainly component products such as control devices and sensors/switches. The result is the current three-base production system in Japan, China, and Thailand.

The azbil Group is not only establishing and expanding overseas production bases, but is also optimizing its global production system, including domestic factories. As part of this effort, the production function of Azbil’s Isehara Factory was transferred to nearby Shonan Factory in spring 2019. Originally, Shonan Factory produced automatic control valves, valve positioners, differential pressure / pressure transmitters, liquid level gauges, etc., but now it produces system and component products formerly produced in Isehara.

Under the current production system, products produced both in Japan and overseas include those requiring advanced manufacturing technology, mass produced products such as component products, and high-mix low-volume products that require processing and welding. Products that require more precise and advanced production technology and equipment are produced at Shonan Factory. In the future, by standardizing processes and equipment, improving the level of production control and quality control for high-mix low-volume production, and further expanding the scale of overseas production, the company aims to increase the percentage of overseas production from the current 25% (approximately) to the mid-30% range in about five years. Also, to prepare for a situation where a major disaster shuts down the production of a base, the Group has been establishing a business continuity plan for production that allows the other bases to take over the lost functions.

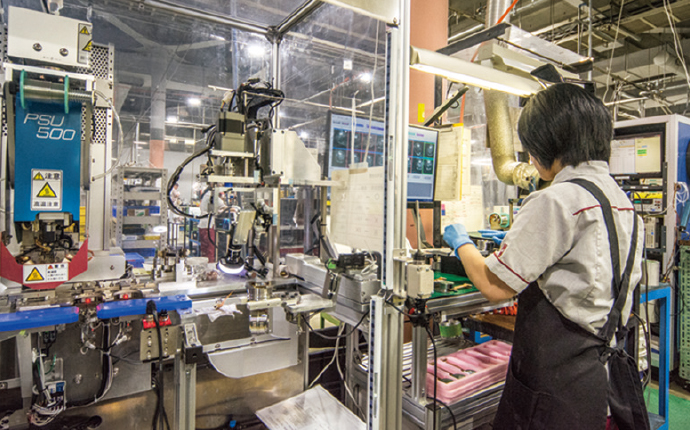

Automatic soldering machine for the sensor parts board of differential pressure / pressure transmitters. AI-based image processing judges the quality of the soldering.

Taking on the challenge of automating high-mix low-volume production that creates high-value-added products

Azbil’s Shonan Factory and Fujisawa Technology Center, which are centers for technology development, are positioned as the “mother factory” in Azbil’s global production system. With the challenges of next-generation production in mind, their job is to create, verify, and lead.

First, while working to establish new production technology that utilizes the latest advances, we are working to create production processes that produce high-value-added products unique to Azbil by achieving automatic microassembly processing using advanced digital technology like AI for our microelectromechanical system (MEMS) sensor package, which is a super-small device that integrates mechanical elements with electronic circuits.

Regarding verify, we will further strengthen our support for high-mix low-volume production and customized production. Azbil produces more than 7,000 types of control valves and 8,000 types of differential pressure / pressure transmitters (counting all the combinations of optional specifications) so that we can meet the unique needs of our customers in the optimal way. A flexible production line that produces such a large variety of products is indispensable. As this complicates the production process, preventing human error becomes an important issue to ensure quality.

As such, Shonan Factory, in cooperation with Azbil’s solution development departments, is establishing an inspection system that utilizes AI and big data to prevent human errors, and is building a system so that production processes that take dozens of steps to go from sensors to the final product can be traced and centrally managed in a database. For processes where human labor and judgments using human know-how have previously been required, AI or Internet of Things (IoT) technology has been utilized to establish an advanced automation system. Manufacturing with thorough quality control has been achieved.

In high-mix low-volume production and also in customized production, we believe it is essential to increase production efficiency and optimize quality, cost, and delivery (QCD) to provide azbil value to our customers.To that end, the standardization of production processes and parts is being undertaken starting from the planning phase, and detailed standardization and optimization are being implemented. This makes it possible, for example, to solder multiple types of products in a flexible production process, or to include a part of a circuit that was not included in the package in the past.

Azbil’s mother factory leads in production, logistics, procurement, and human resource development

Shonan Factory will lead the company in developing its production technology and standardized production processes for the azbil Group’s production bases. Standardizing product design and production processes makes it easy to transfer production to overseas bases. The mother factory’s role is to lead the company in production management, quality, logistics, and procurement initiatives.

In addition, azbil Group engineers from overseas production bases are dispatched to Shonan Factory or Fujisawa Technology Center for a certain period of training in production technology or production management. This kind of human resource development has been continuously implemented, and many of the employees who were trained are now leaders at the production bases in Dalian, China or Thailand.

Contributing to a sustainable society and continuous company growth

We are also making efforts to contribute to the achievement of a sustainable society. This is because we believe that efforts toward a sustainable society will lead to the continuous growth of our corporate group.

In addition to using IT and AI technology to save energy in the production process itself, we use energy-efficiency design to reduce the amount of material used in products, and also to introduce reusable raw materials and reduce the number of parts. We are also working to reduce the waste material from production processes. Further, since Azbil’s sustainability goals were certified as science-based targets,*1 we are strengthening our initiatives, including those directed at the supply chain.

In the future, the azbil Group will further optimize its global production system, regardless of whether the base is domestic or overseas, to provide the latest technology, products, and services in a timely and high-quality manner to meet customers’ wide variety of needs, and to contribute to the realization of a sustainable society and sustainable business.

Major production bases of the azbil Group

*1 Science-Based Targets

GHG emission reduction goals that are set based on scientific evidence to keep the global temperature increase below 2 °C compared to pre-industrial levels.

Science Based Targets (SBT) is an organization whose purpose is to encourage companies to set greenhouse gas (GHG) emission reduction goals as a kind of public promise. Companies apply to participate in the Science Based Targets initiative (SBTi), and if their targets meet SBT’s standards, the targets are certified as “science-based targets.”

This article was published on January 1, 2021.