Working with Our Customers to Resolve Semiconductor Manufacturing Issues

Continuous improvement and an innovative mindset for solving problems faced by customers and for keeping pace with ever more advanced, miniaturized, and evolving semiconductor manufacturing technology

Azbil, which has been providing vacuum gauges to the semiconductor market for 20 years with a focus on sensing technology, now offers sapphire capacitance diaphragm gauges that resist degradation in accuracy over time. By working closely with customers to solve problems and maintaining an innovative, forward-looking stance, we have created new value for users of our products.

- Accuracy degradation in vacuum gauges for semiconductor manufacturing

- Sapphire diaphragm for higher corrosion resistance and reproducibility

- Continuous improvement and value creation to meet customers’ needs

Accuracy degradation in vacuum gauges for semiconductor manufacturing

Semiconductors make possible the digital products that are essential to our daily lives, such as smartphones, tablets, and PCs, as well as home appliances and automobiles. The market continues to grow significantly, and elements and technologies have evolved for the manufacture of more advanced and finer semiconductors. Azbil Corporation has contributed to the semiconductor industry for more than 20 years by providing sensors that are incorporated into semiconductor manufacturing equipment. In recent years, we have focused on diaphragm vacuum gauges. Semiconductor manufacturing processes include deposition, in which a thin film that becomes the material for wiring and transistors is formed on thin plate-shaped wafers, and etching, which removes the unnecessary part of the film and processes it into specific shapes. These processes must be carried out in an environment with very few impurities and in a vacuum chamber maintained at an appropriate degree of vacuum. Diaphragm vacuum gauges are used for high-accuracy measurement of the state of the vacuum in the chamber. Inside the vacuum gauge, a reference chamber, which is in a high state of vacuum, and a measurement chamber are separated by a diaphragm. An ultra-small change in the pressure of the gas in the measurement chamber cause it to differ from the pressure in the reference chamber, which deflects the diaphragm. The state of the vacuum can be measured by sensing the deflection.

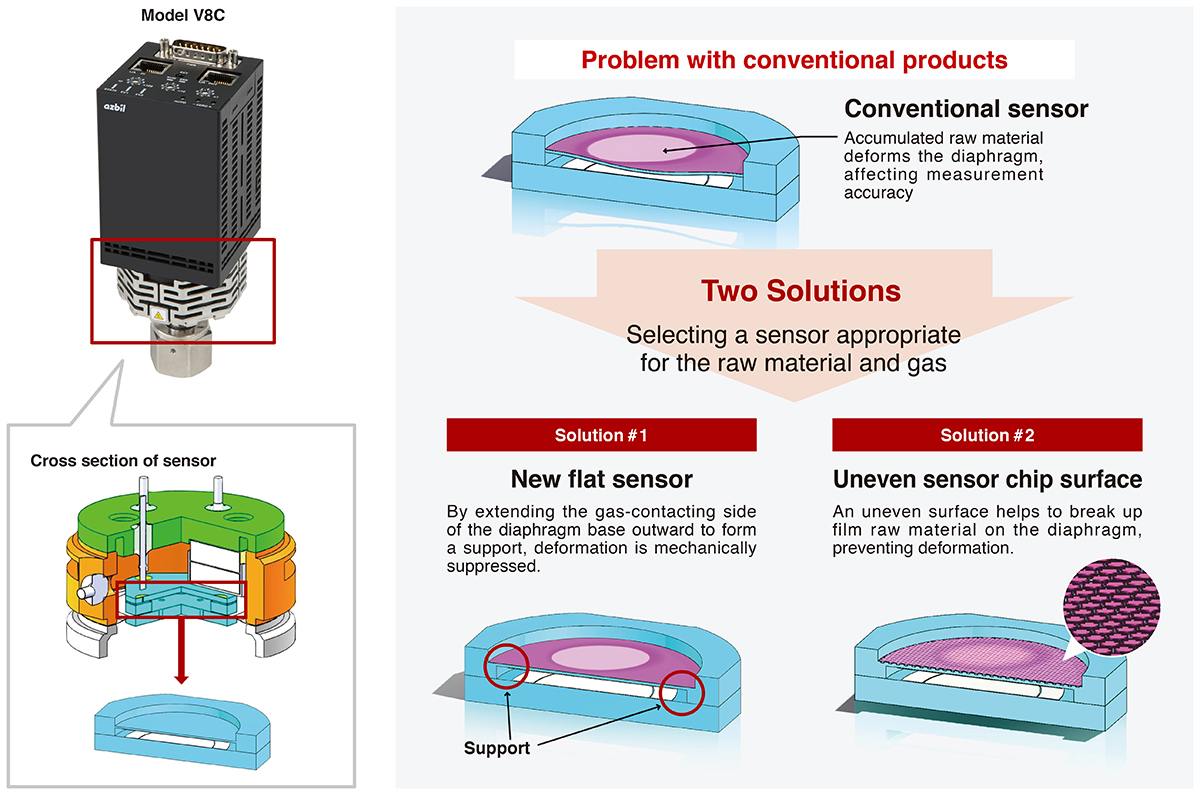

Conventionally, nickel alloy foil has been widely used as the material for the diaphragm. There has been a long-standing problem, however, that the basic accuracy of the vacuum gauge changes over time. This occurs because the raw materials of the film accumulate on the diaphragm in the deposition process and because the diaphragm is corroded by fluorine and chlorine gases used in the etching process.

Sapphire diaphragm for higher corrosion resistance and reproducibility

To counter these problems Azbil considered using sapphire as the diaphragm material. Sapphire, which has a single crystal structure, is highly resistant to corrosive gases and has excellent stability against thermal changes. If it is used in a measuring device, the repeatability and accuracy of measurement will be excellent. However, sapphire is difficult to process, so to commercialize products we worked to develop new MEMS*1 processing technology, signal processing technology, and sensor packaging.

In 2006, we began work on a sapphire capacitance diaphragm gauge that uses an extremely thin artificial sapphire chip. In 2011, we released our models SPG5 and SPG6, which have technical improvements to address the degradation of accuracy.

These gauges incorporate a diaphragm that is slightly thinner in the center, a unique shape that prevents unnecessary deflection due to the accumulation of film raw material. In addition, since uneven accumulation causes deflection and measurement errors, minute holes are made in specific places on the sapphire disk that covers the diaphragm in order to encourage balanced accumulation. Additionally, in order to suppress accumulation, we developed a trap structure consisting of approximately 4,000 passages in front of the diaphragm which acts as a filter to remove film raw material. Thanks to these new processing technologies and the creativity of Azbil developers, measurement errors were reduced significantly.

Solutions incorporated into sapphire capacitance diaphragm gauge models V8C and V8S

Continuous improvement and value creation to meet customers’ needs

Currently in Japan, products from the United States and Europe dominate the market for vacuum gauges in semiconductor manufacturing, but Azbil, a Japanese manufacturer, has provided products that meet market needs both in and outside of Japan. This was made possible because our R&D departments make a practice of visiting customers’ facilities, learning about the problems they face, and feeding back that information to stimulate further improvements and new development.

In semiconductor manufacturing, innovative elements and processing methods often involve the use of novel gases. However, these new gases may result in corrosion and the accumulation of raw materials inside the gauge, degrading measurement accuracy. Therefore, as long as semiconductor functions continue to advance, there will be a need to improve vacuum gauges to meet the changing needs of customers. Azbil’s strength lies in listening to its customers at their manufacturing sites and working to make continuous improvements that solve problems, which leads to the development of useful products.

In addition, with determination to take on the challenge of dominating the vacuum gauge market in place of U.S. and European vendors, we have been working to enhance product competitiveness, which led to the release of new sapphire capacitance diaphragm gauge models V8C and V8S. Models V8C and V8S operate in temperatures as high as 200–250 °C. The new flat sensor and uneven sensor developed by MEMS processing technology have enhanced the versatility and flexibility of our products, allowing them to be used with new gases in the etching process. In addition, we have established a MEMS R&D base with a full-fledged clean room at the Fujisawa Technology Center, which is Azbil’s center for R&D, in an effort to further integrate R&D and production.

Diaphragm vacuum gauges with excellent corrosion resistance, repeatability, and reliability can reduce the frequency and time needed for periodic adjustments, which increases productivity in semiconductor manufacturing. Also, from a broader perspective, because advanced semiconductors will lead to the increased sophistication of smartphones and other electronic devices and of infrastructure, our products will contribute to a society that continually innovates new technologies. Guided by the azbil Group philosophy of creating value together with customers at their site, and in order to make contributions that lead “in series” to a sustainable society, Azbil will continue to work alongside customers to tackle and solve the challenges they face, challenges that are continually changing along with innovations in semiconductor technology.

*1 MEMS (microelectromechanical system)

MEMS refers to ultra-compact devices or systems which integrate mechanical components like sensors and electronic circuits on a substrate such as silicon by applying microfabrication techniques based on the technology used in semiconductor manufacturing.

This article was published on January 1, 2024.