Decarbonization Initiatives

Global warming is a worldwide challenge. Members of the azbil Group are working together proactively to take measures to save electricity and conserve energy in their business activities, while bearing in mind the importance of their role in helping customers and society to significantly reduce CO2 emissions.

Also, the azbil Group also supports policies based on various agreements to take measures to prevent global warming, including the Paris Agreement.

We support the Japanese government’s course change toward carbon neutrality, and we comply with the Act on Rationalizing Energy Use and the Act on Promotion of Global Warming Countermeasures, which are national laws on climate change. In accordance with these laws, we report to the government once a year on our energy consumption, our progress on energy conservation targets, our energy reduction plans, and the amount of our greenhouse gas emissions.

Regarding our initiatives for decarbonization as a company, based on our 2050 Long-Term Vision for Reducing Greenhouse Gas Emissions we have formulated policies and plans and are working to implement them. Under the direction of the azbil Group's executive officer in charge of environmental management, we have appointed officers in charge of each large-scale business site and are working together with management. In the environmental management system, which is centered on the azbil Group Environmental Committee and cuts across business divisions and major regional overseas production sites, we have set a common GHG reduction target which is an SBT-certified 1.5 °C target. To meet this goal and check progress, we share specific targets for energy reduction and utilization of renewable energy and hold regular meetings. Additionally, there are regular meetings between the Environment Promotion Department, which is a coordinating department, and the person in charge of environment at each Group company to follow up on progress. In addition, Azbil Corporation holds an Environmental Managers' Meeting six times a year as an energy management organization. It is headed by an Azbil executive officer and includes the director of each business site. There, we create CO2 reduction targets and achievement plans, check progress, and provide feedback to the workplace to promote proactive efforts.

We have introduced our own energy management solutions, such as EneSCOPE™ or Cloud System for Buildings EM, at our main locations. By visualizing power usage and other energy usage, we are working to effectively optimize the use of energy in production and office environments, which will lead to energy conservation that is linked with our business lines.

We utilize the knowledge gained through these efforts to contribute to the reduction of GHG emissions from our customers and society.

Our Long-Term Vision for Decarbonization

In addition to reducing the environmental impact of our own business activities and of our supply chain, and drawing upon the technologies and know-how obtained by doing so, the azbil Group will make use of its measurement and control technology to find solutions to the environment-related problems faced by our customers. In doing so, we will help to preserve the environment through our core businesses.

We set our environmental agenda and advance our environmental initiatives with an awareness of related global developments, including the U.N.’s adoption of Sustainable Development Goals (SDGs) and the entry into force of the Paris Agreement. In particular, we view response to the global warming crisis as a most important issue, and we aim for a low-carbon society.

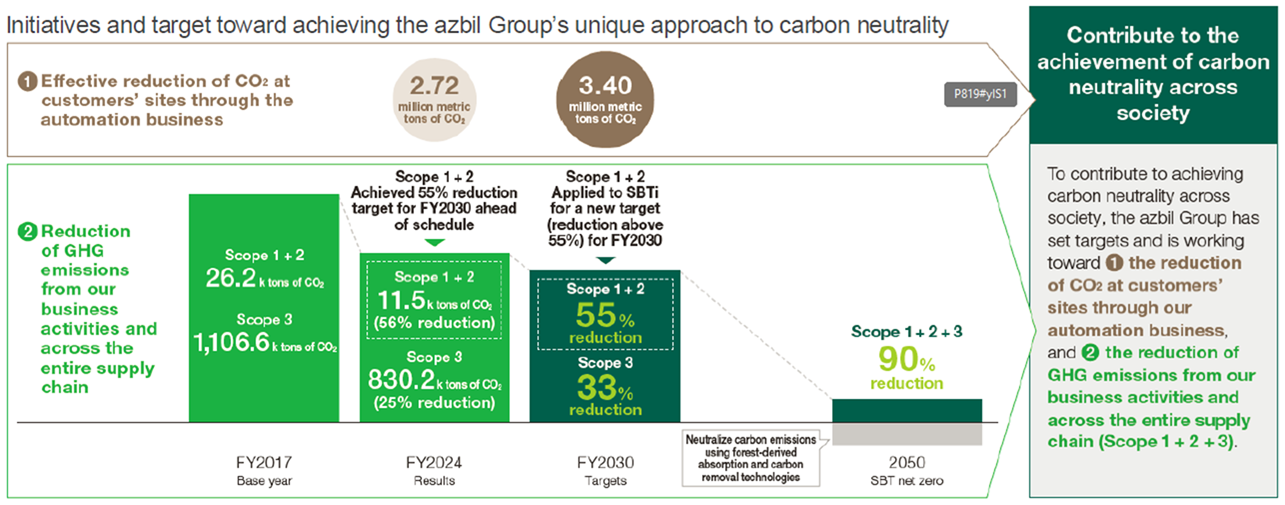

Since 2020, we have been working toward realizing carbon neutrality, as laid out in our 2050 Long-Term Vision for Reducing GHG Emissions; this aims to reduce GHG emissions from our business activities (Scope*1 1+2) to substantially zero by 2050. As our new long-term vision, we have set a target of achieving net zero by reducing emissions by more than 90% (compared to FY2017 levels) throughout the value chain (Scope 1+2+3) and neutralizing residual emissions*2. In line with this, the FY2030 target for reducing indirect GHG emissions (Scope 3) throughout the value chain (excluding Scope 1+2) has been raised from 20% to 33% (compared to FY2017 levels). This new long-term vision satisfies the SBTi*3,*4 criteria and has received net-zero certification.

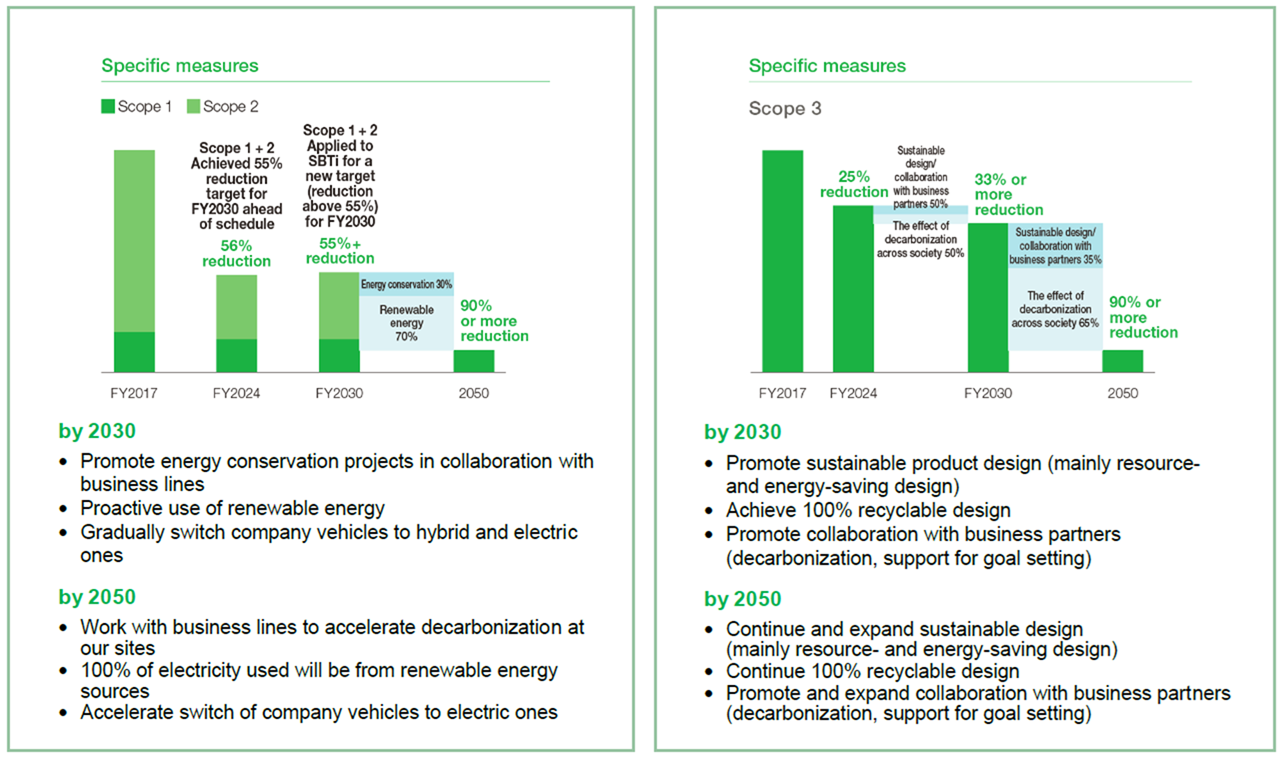

To achieve our SBT Net-Zero Target by 2050, we are developed a decarbonization transition plan and we will advance specific reduction initiatives, such as promoting the azbil Group’s unique sustainable design for all new products, collaborating with our business partners, applying to our own businesses the energy-saving technologies we have developed at our customers' sites, and harnessing renewable energy.

Group decarbonization targets

Net-Zero Target: by 2050 (net-zero certification)*5,*6

Achieve net-zero GHG emissions throughout the value chain (Scope 1+2+3)

Reduce emissions throughout the value chain by at least 90% (compared to FY2017 levels) and neutralize residual emissions

Medium-Term Target: by FY2030

Reduce GHG emissions (Scope 1+2) from business activities by 55% (compared to FY2017 levels)*5

Reduce indirect GHG emissions (Scope 3) throughout the value chain (excluding Scope 1+2) by 33% (compared to FY2017 levels)*6

*1 Scope 1: Direct GHG emissions from the business itself (fuel combustion, industrial processes)

Scope 2: Indirect emissions related to the use of electricity, heat and steam supplied by other companies

Scope 3: Emissions from other companies associated with the business’s activities (indirect emissions other than those covered by Scope 1 and 2)

*2 Residual emissions: GHG emissions within the azbil Group value chain that cannot be fully eliminated.

*3 SBTs: science-based targets for reducing GHG emissions that aim to keep the increase in global-average temperature to well below 2°C above pre-industrial levels, and to limit it to 1.5°C above pre-industrial levels by the end of the century.

*4 SBTi: An international collaborative organization that aims to achieve the GHG reduction targets (SBTs). It was jointly established in 2015 by the Carbon Disclosure Project (CDP; an organization of institutional investors that promotes the disclosure of information on climate-change measures), the World Resources Institute (WRI), the World Wide Fund for Nature (WWF), and the UN Global Compact. As of October 2024, approximately 1,300 companies in Japan had obtained SBT certification, and Japanese companies are currently expanding SBT initiatives at an even faster pace compared to the global average.

*5 Targets for Scope 1+2 apply to Azbil Corporation, its domestic consolidated subsidiaries and major overseas production bases (accounting for more than 95% of the Group’s total GHG emissions)

*6 Targets for Scope 3 apply to Azbil Corporation and its consolidated subsidiaries.

Decarbonization transition plan

In response to the societal shift toward decarbonization, we are actively contributing to solutions for the energy challenges faced by both our customers and society at large. In addition, we have developed and are implementing a transition plan to support decarbonization efforts.

Furthermore, the following 2050 net zero target covering all CO2 emissions (Scope 1 + 2 + 3) has been certified as a net zero target by the Science Based Targets initiative (SBTi) (October 2024).

Regarding Scope 1 + 2 emissions, we achieved our 55% reduction target for FY2030 ahead of schedule in FY2024. Consequently, we are currently applying to the SBTi for a new, upwardly revised target for FY2030.

For Scope 1 + 2, we are leveraging our extensive expertise in energy conservation and actively implementing energy visualization systems across the entire Group, and we are focusing our energy conservation efforts from two perspectives: improving operations and upgrading facilities. In addition to strengthening energy conservation efforts in collaboration with business lines, we will actively incorporate renewable energy sources, taking additionality into account. We aim to accelerate these initiatives with the goal of transitioning to renewable energy for all electricity consumption by 2050.

As for Scope 3, to reduce CO2 emissions from the use of purchased products and services, as well as products sold, we will continue and expand our sustainable product design efforts, including resource-saving and energy-saving designs. To help achieve carbon neutrality across society, we also support our business partners’ decarbonization efforts by conducting surveys and engaging in detailed discussions on decarbonization initiatives. Looking toward 2050, we are evaluating scenarios based on our current policies and considering the projected decarbonization across society.

External evaluations

The azbil Group's response to CDP regarding our efforts to address climate change is as follows: Received a B*2 rating in CDP 2024*1.

Answers to CDP 2025 Questionnaire (Japanese)

Answers to CDP 2024 Questionnaire (Japanese)

Answers to CDP Climate Change 2023 Questionnaire (Japanese)

*1. A program to disclose corporate climate change risk, created by the international nonprofit organization CDP. It investigates the status of climate change initiatives carried out by participating corporations every year and officially publishes the aggregated results. It also gives each corporation an individual rating for the status of its initiatives in an eight-step evaluation with A as the highest rating.

*2. We had been selected for the A List for three consecutive years and have filed a score appeal with CDP regarding our CDP Climate Change 2024 score of “B.”

Results for the Fiscal Year 2024

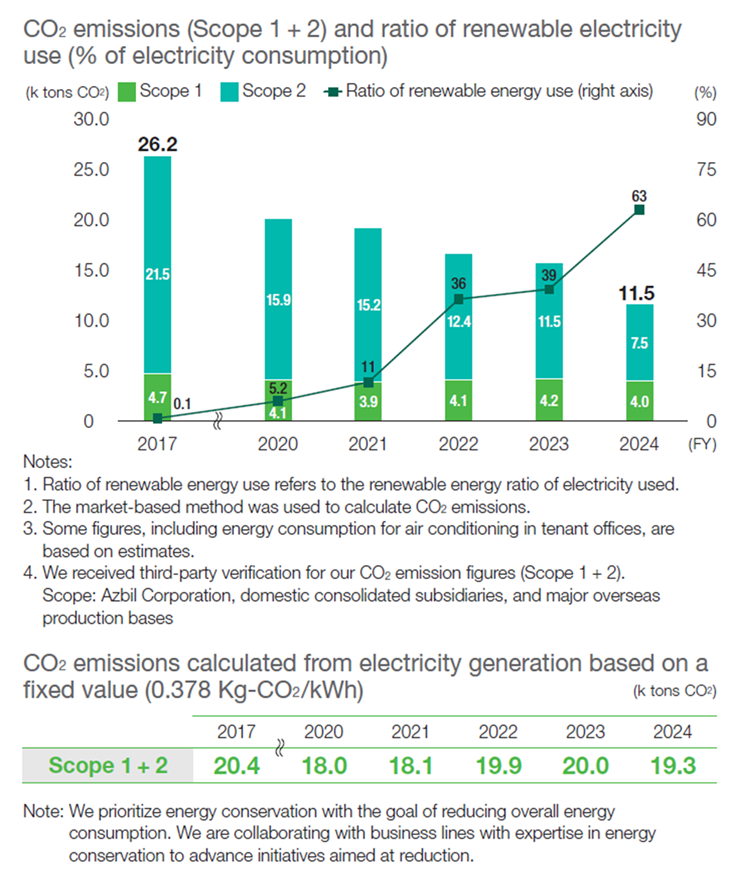

CO2 emissions from our own business activities (Scope 1 and 2) in FY2024 were 11 thousand metric tons (a 56% reduction from FY2017), achieving the FY2030 target ahead of plan.

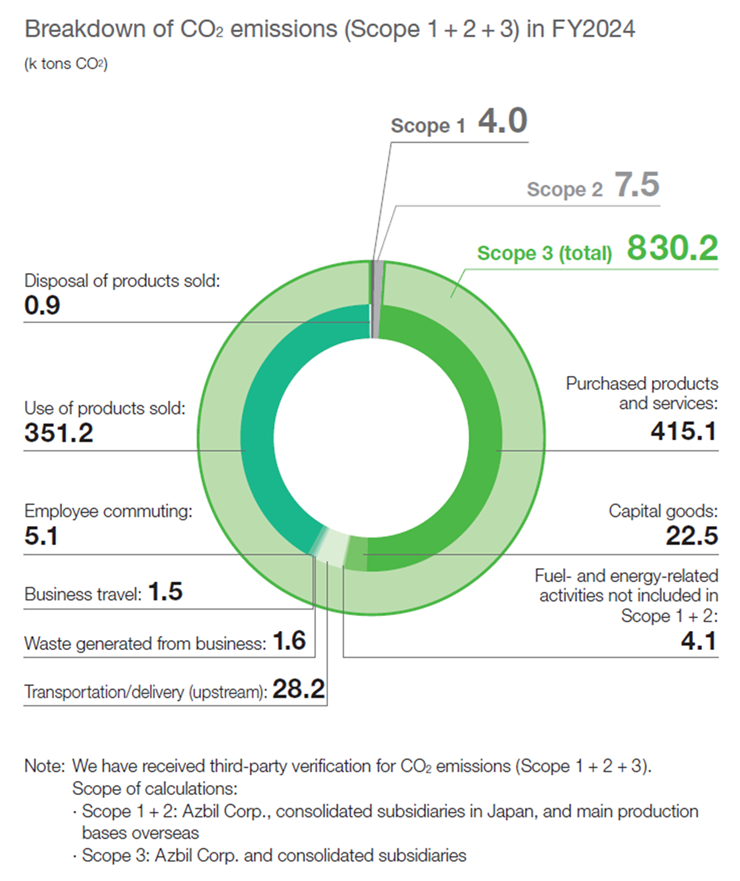

In addition, CO2 emissions across the entire supply chain (Scope 3) were 830 thousand metric tons (a 25% reduction compared with FY2017), tracking steadily toward achieving our target.

To reduce CO2 emissions from our business activities, we have switched to using 100% renewable energy sources, including off-site corporate solar power purchase agreement (PPA) services, for the electricity used at the Fujisawa Technology Center. Renewable energy sources accounted for 63% of the Group’s total electricity consumption in FY2024. Going forward, we will proactively install solar power generation equipment, primarily at our overseas production sites.

To reduce CO2 emissions across the entire supply chain, we are promoting sustainable design, such as resource- and energy-saving design, and cooperating with business partners to reduce CO2 emissions from the use of products sold, and products and services purchased, which account for 90% of total emissions.

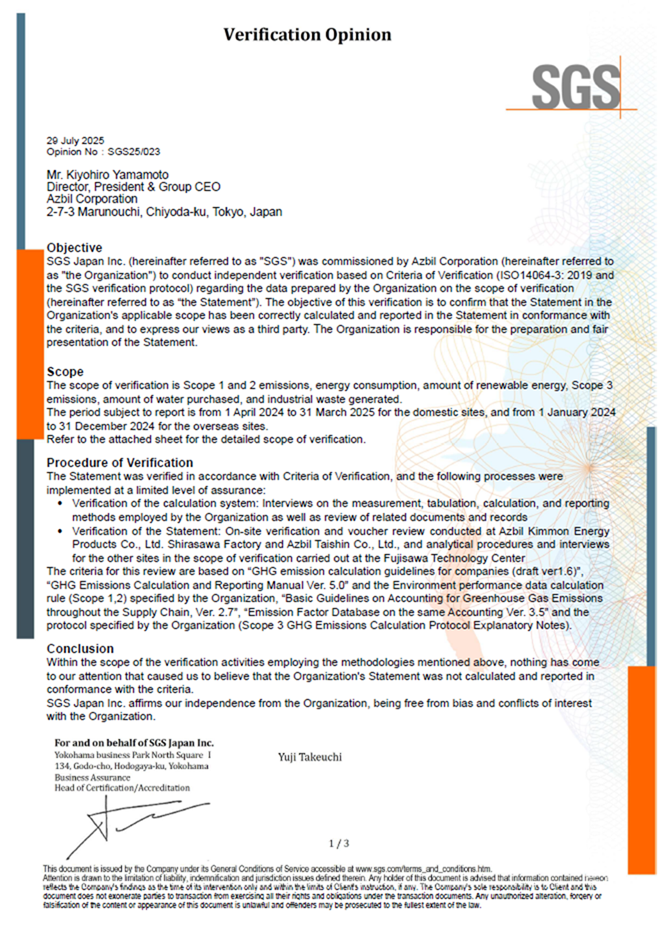

Greenhouse Gas Emissions Verification Statement

(Click here for more detail)

CO2 Emissions (Scope 1+2) produced by azbil Group bases

(Metric tons of CO2)

| FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Scope1 + 2 | 19,066 | 16,552 | 15,734 | 11,471 |

| Scope1 | 3,880 | 4,102 | 4,246 | 3,954 |

| Scope2 | 15,186 | 12,449 | 11,488 | 7,516 |

| Scope3 | 847,591 | 1,020,188 | 885,902 | 830,164 |

Included:

Scope 1 and 2 Azbil Corporation, domestic consolidated subsidiaries, major overseas production sites

Scope 3 Azbil Corporation, consolidated subsidiaries

Sustainability

- azbil Group’s Sustainability

- Environtment

- Social

- Governance

- Social Contribution

- Sustainability-related References

- azbil Group CSR Hotline

- Contact us

- Sitemap