Diagnosis Overview

About our Valve Diagnostics Service

Introduction video

Our Valve Diagnostics Service analyzes and diagnoses information collected through the control valve maintenance support system PLUG-IN Valstaff to discover and predict valve abnormalities that could previously be found only through overhaul inspections. This helps you to prevent facility shutdowns caused by control valves, allows you to focus on the actual work of maintenance, and helps you to streamline work the smart way.

Delivery of Valve Diagnostics Service diagnoses

Value of diagnosis service

Valve health visualization

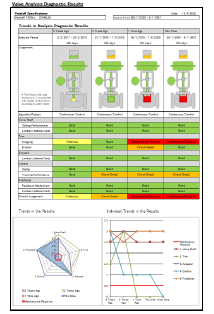

The valve diagnostic report gives a quick overview of valve health

Smart Valve Positioner

Quantification of

valve motion

Valstaff

Visualization of

motion

Visualization of

operation

Smart Valve Positioner diagnostic parameter information

Service details

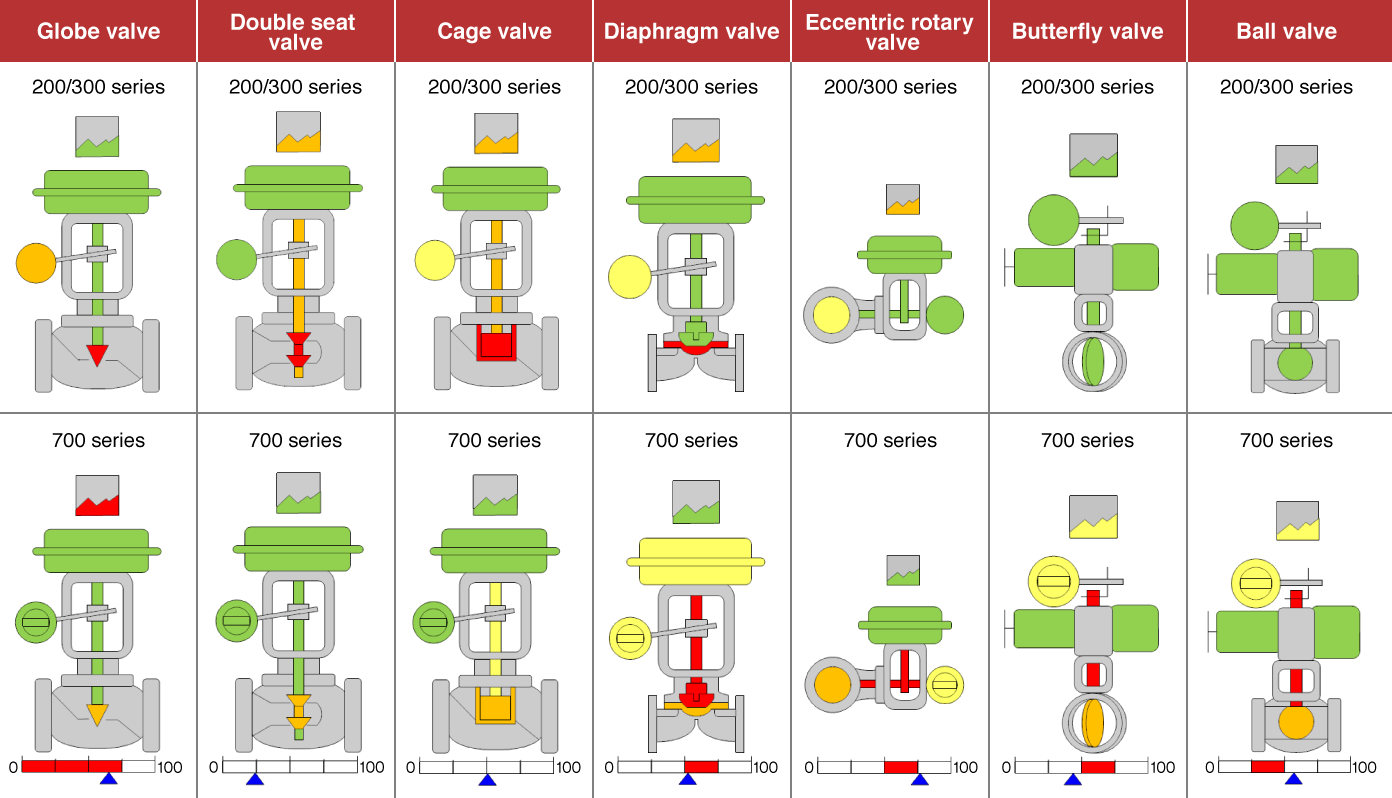

Applicable valves

7 supported valve types: globe, double seated, cage, diaphragm, eccentric rotary, butterfly, and ball.

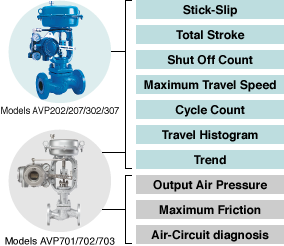

* 200/300 series:Models AVP202/207/302/307

700 series:Models AVP701/702/703

Diagnosable conditions

The following phenomena can be detected by analyzing various combinations of operating data.

| Phenomenon | Azbil’s Smart Valve Positioners (with HART/FOUNDATION Fieldbus support) |

|

|---|---|---|

| Models AVP202/207/302/307 | Models AVP701/702/703 | |

| Sticking | ○ | ○ |

| Galling | ○ | ○ |

| Damaged trim, clogging | ○ | ○ |

| Hunting after input of certain values to the positioner | ○ | ○ |

| Slowdown (underperformance before sticking/galling) | ー | ○ |

| Inadequate performance for fluid differential pressure | ー | ○ |

| Insufficient supply air pressure | ー | ○ |

| Positioner air circuit problems | ー | ○ |

Types of diagnosis

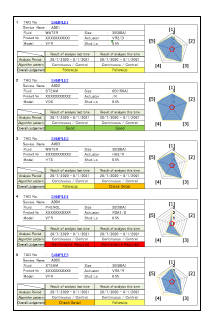

Three types of diagnostic service meet different needs at production sites.

Primary screening

diagnosis

This identifies which valves among hundreds at the plant require close monitoring, and tells their condition.

Learn moreDetailed

diagnosis

Detailed analysis of customer-specified valves and valves assessed by primary screening as needing attention, in order to gain in-depth understanding of problem conditions.

Comparative

verification

Even valves with completely identical specifications have different characteristics depending on the fluid used and the operating conditions. These characteristics can be understood by repeated comparative verification.

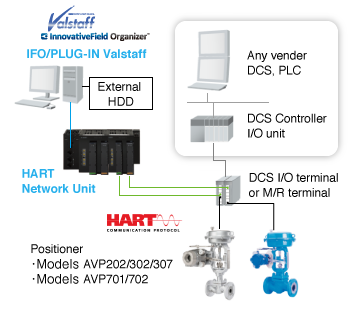

Tools required for diagnosis

The Valve Diagnostics Service collects and accumulates various diagnostic parameters held by Azbil’s HART® communication–compatible Smart Valve Positioner diagnostic devices in the control valve maintenance support system PLUG-IN Valstaff, and uses this valve operating data to make diagnoses.

Learn more

Contact information for inquiries about the Valve Diagnostics Service

- Valve Diagnostics Service

- Diagnosis Overview

- Types of diagnosis

- Service Menu

- Dx Valve Basic Service plus

- Diagnostic Tools

- Diagnosed Cases

- Use Cases, Customers, and Results

- Avoid Sudden Equipment Shutdown

- Optimizing Maintenance Plans (to TBM + CBM)

- Faster Equipment Startup after Periodic Maintenance

- Diagnostic possibilities with the Smart Valve Positioners 700 Series

- FAQ

- Introduction of our capability for factories and plants

- Maintenance Support

- Life Cycle Support

- Energy-Saving Program for Factories and Plants

- Equipment Diagnosis Support for Factories and Plants

- Advanced Automation Company Training Center