Tokyo Rinkai Heat Supply Corporation

Tokyo Rinkai Heat Supply Corporation, a district heating and cooling business serving Tokyo’s Rinkai Fukutoshin area, upgraded the central monitoring systems at its plants and integrated their distributed control systems. 1 On this occasion, the company extensively revised and reconstructed its system for optimizing operation, making operation highly efficient by selecting which heat source equipment, etc., to operate based on data such as current energy demand trends, weather conditions like temperature and humidity, and past operation data.

The Tokyo water front area where

Tokyo Rinkai Heat Supply Corporation is providing heat

Factories and Plants Other (Markets and Industries) Reliable Operation Operation Improvement Industrial Automation Control and Monitoring Systems and Software Pressure Gauges (Pressure Sensors) and Differential Pressure Gauges (Differential Pressure sensors) Flowmeters

Products/Services Provided

Making use of a new operation support system to achieve optimal operation of heat source equipment

Established in 1990 to provide heating and cooling services across Tokyo’s Rinkai Fukutoshin area, Tokyo Rinkai Heat Supply Corporation produces 7 °C chilled water and 80 °C heated water at its three district heating and cooling plants in Daiba, Aomi Minami, and Ariake Minami (all in Tokyo), and provides heat in these districts for office buildings, hotels, hospitals, recreational facilities, TV stations, etc. At the Ariake Minami and Daiba plants, the company helps to reduce CO2 emissions and save energy by using waste hot steam emitted from the Ariake Incineration Plant.

“Since we began providing heat in 1995, we have continued to improve operational efficiency while putting our efforts into providing a reliable energy supply. In the process, we have successfully lowered energy rates a total of five times, because our focus is always on lowering costs for our customers,” says the company’s president, Masaru Hosoi.

In around 2006, ten years after the plants began operation, the company started to discuss an upgrade of the plants’ central monitoring systems, which had begun to age. Uppermost in mind during the discussions was the integration of the monitoring systems at the three plants.

“Until then, the three plants had independent systems. We thought that the upgrade was the right moment to put these plants’ systems together and construct a shared system so that we could improve operability by standardizing procedures for operators working at the different plants. We also wanted a heat supply that could meet customer demand just by furthering the development in the Rinkai Fukutoshin area, so we needed to establish a system that enabled these plants to cooperate with each other to achieve various aims, such as cost reduction,” explains Takayuki Hatabe, director of the Engineering Department.

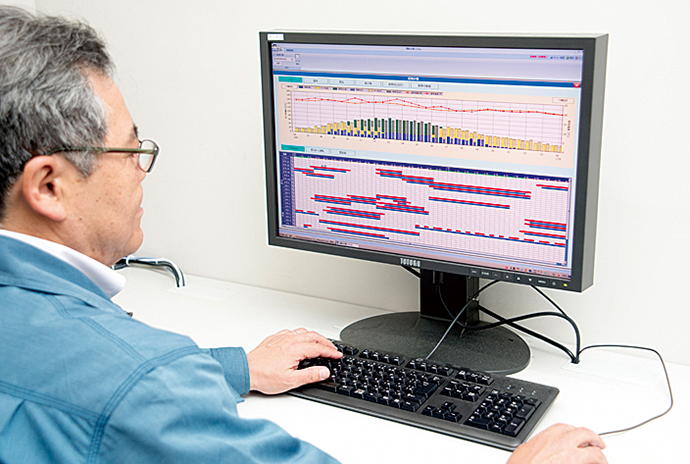

“Operators working at the plants decide the appropriate number and combination of heat source devices to operate according to the current energy demand and weather conditions like temperature and humidity. The old operation support systems were only capable of predicting customers’ energy consumption, so our operators had to make decisions based on their experience. As a matter of course, the decisions varied depending on the operator, and human judgment is limited. So we wanted to install a new operation support system that could help operators by providing guidance for operating the heat source equipment so that we could make our heat production more efficient,” says Takashi Yamaguchi, director of the Ariake-Minami Management Office.

The central monitoring room at the Ariake Minami plant. Operators at the three plants can now share the same view through their screens in their central monitoring rooms, which enables them to reference information about problems that occurred at other plants and how they were handled. The current operation support system has implemented a unique function that shows the approximate price in yen of the electricity and/or gas being used to produce one gigajoule of energy.

The same operation support system monitors can also be accessed and viewed from offices at the headquarters, allowing relevant departments and management personnel to check the status of operations.

Upgrade process examined closely to guarantee a reliable heat supply

DSTJ™3000 Ace+ differential pressure transmitters measure the pressure of the main pipes for heat and chilled water.

Tokyo Rinkai Heat Supply Corporation asked several companies, two of which were suppliers of the existing systems, to submit estimates and upgrade plans. After a comprehensive assessment of the plans in terms of the technological skill and past performance of the company, cost, maintenance system, etc., Azbil Corporation, the supplier of the former system at the Ariake Minami plant, was selected as the partner for the new project.

“We were favorably impressed by Azbil’s past performance, such as its cordial handling of maintenance work at our plant, and when thinking about future operations, we felt comfortable with Azbil’s plan, which stated their intent to hear operators’ requests at any time and continually incorporate them into the system,” says Mr. Yamaguchi.

At the start of the project, Azbil conducted a survey to gain insight into the opinions and requests of all operators working at the three plants. Incorporating as many of the requests as possible, Azbil constructed a system which was ideal for the sites, based on a highly dependable open automation system called Industrial-DEO™, and including a utility optimization software package for power plants with heat source equipment in order to ensure optimal operation. One of the important challenges for Azbil was to find a way to make efficient progress in the system integration work while maintaining the reliability of the heat supply.

“There are hospitals in the area we serve, so we can never interrupt the heat supply. Upgrading a system while it is running a plant is difficult and requires caution. We spent one year in discussions over the selection of the measurement and control system and the construction methods necessary to integrate the systems, repeatedly checking and adjusting fundamental matters before we finally settled on the details of the upgrade. The construction period was planned to be one year per plant. We made a detailed plan for five-year construction starting from the Aomi Minami plant, and then continuing to Daiba, Ariake Minami, and finally the headquarters in that order,” says Mr. Hatabe.

A MagneW™3000 FLEX+ electromagnetic flowmeter measures flow rate while a DSTJ3000 Ace+ transmitter measures pressure.

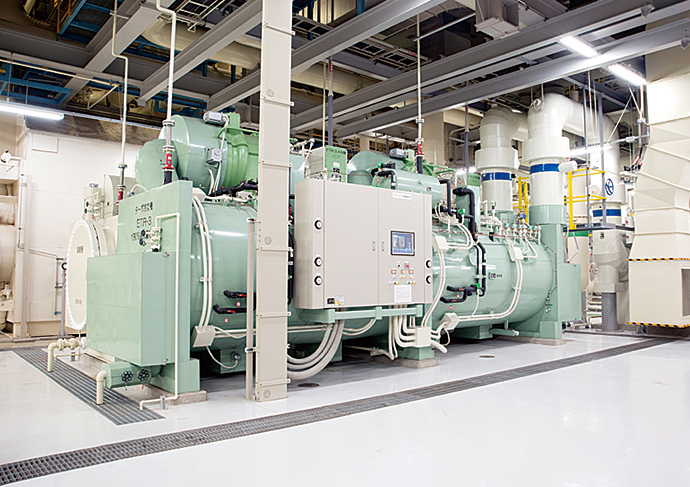

A turbo chiller uses electricity to produce chilled water.

Electricity and gas contracts factored in to achieve minimum-cost operation

Thanks to careful preparation, the upgrade work, which began in 2010, made smooth progress and was completed for all locations by the end of 2014. The same project team, composed of the same members, carried out the work for all three district plants, so the knowledge they gained from preceding upgrade work was effectively leveraged in subsequent work.

“Plant operational data that has been accumulated since the start of operation is one of the very important sources of information we can use to achieve optimal operation. We handled that data very carefully in order not to lose any of it during the upgrade work, and after considering the best way to import it into the new system, we successfully did so at each plant,” comments Mr. Hatabe.

After the upgrades, the new system can predict the demand one hour or 24 hours in the future by referencing the operation data for the same time in the previous year. It also imports weather data, such as the outdoor temperature and humidity, which can greatly affect plant operation. It then presents operators with the best number and combination of devices to achieve optimal operation in terms of cost, CO2 emissions, and operating efficiency. “There are two types of heat source equipment, electricitydriven and gas-driven. The new system uses the best combination of both to achieve energy efficiency,” says Mr. Yamaguchi.

Tokyo Rinkai Heat Supply Corporation is determined to continue its pursuit of efficiency. “The series of deregulation measures advanced by the Japanese government will force us energy service companies to compete more intensely. So increasing the reliability of our heat supply and becoming more cost-competitive are important challenges for us. The key to addressing these challenges is to make the best use of our new system. We are looking forward to Azbil’s help on this point also,” says Mr. Hosoi.

* Industrial-DEO, DSTJ, and MagneW are trademarks of Azbil Corporation.

glossary

Distributed Control System (DCS)

A system specially developed for the monitoring and control of production equipment and manufacturing processes at industrial plants and factories. Its networked modules work autonomously so that the workload is shared among these components, making it easy to maintain the system safely.

Learn about the customer

President-Director

Director of the Engineering Department

(at the time of the interview)

Director of Ariake-Minami Management Office

Engineering Department

Tokyo Rinkai Heat Supply Corporation

Tokyo Rinkai Heat Supply Corporation

- Location: 3-6-11 Ariake, Koto-ku, Tokyo

- Established: August, 1990

- Business: Supplies heat in the Tokyo waterfront area for heated or chilled water

This case study was published in the 2017 Vol.3 issue of the azbil Group's corporate magazine, azbil.