Mitsubishi Gas Chemical Company, Inc., Niigata Plant

At Mitsubishi Gas Chemical’s Niigata Plant, which produces high-performance chemical products that require delicate control in the manufacturing process, it has been challenging to detect all anomalies in the vast manufacturing equipment and avoid the occurrence of abnormalities. Operational stability and quality assurance have become critical issues. With the introduction of an anomaly detection system, the plant is now able to respond to equipment anomalies in a timely and appropriate manner. This has also significantly reduced the psychological burden on operators.

Factories and Plants Chemicals Electric Power and Gas Quality Control Reliable Operation Maintenance Support Industrial Automation Control and Monitoring Systems and Software

Operational stability and quality assurance are challenges at the high-performance product manufacturing plant

Mitsubishi Gas Chemical Company, Inc. provides chemical products that support industry and daily life under the mission of “Creating value to share with society.” In 1952, it became the first company in Japan to successfully synthesize methanol using domestically produced natural gas that they had extracted themselves. Since then, as a comprehensive methanol manufacturer, it has developed a diverse range of businesses based on their unique technologies, consistently handling everything from resource procurement to process development, production, transportation, and sales.

The company’s main production base, the Niigata Plant, is located in the Niigata region, which is rich in underground resources, and produces a wide range of products, starting with methanol synthesis using natural gas, as well as synthetic resins, electronic industrial chemicals, and bio-products. In recent years, it has been actively working toward carbon neutrality, including collaborating with the city of Niigata to produce biomass-derived methanol. Within the Niigata Plant, Specialty Chemicals Group -2 of Production Department -3 produces Mitsubishi Gas Chemical’s main products, such as MX-Nylon*¹ and engineering plastics*², which are used in food packaging materials, as well as materials used in automotive and housing paints, adhesives, and cardboard strengtheners.

“Due to the nature of the products, the manufacturing equipment used by our department frequently experienced anomalies, such as a drop in reaction temperature and blockages. Moreover, in recent years, veteran operators have been transferred to other departments, making it a critical challenge to stabilize operations and ensure product quality with a team primarily composed of younger staff,” says Kazuya Kato, Manager, Specialty Chemicals Group -2, Production Department -3, at the Niigata Plant of Mitsubishi Gas Chemical Company, Inc.

Confirmed that anomalies can be detected earlier than they can with standard DCS monitoring

As Specialty Chemicals Group -2 searched for ways to resolve the issues, they became interested in Azbil Corporation’s BiG EYES™ online anomaly detection system, which was presented at an on-site seminar held by the electrical equipment section of the Niigata Plant in March 2019.

“BiG EYES is an advanced tool that uses AI to identify the signs of anomalies, unlike the method of detecting them by monitoring measurement value alarms using a DCS*³. While there are similar products from other companies, we felt that Azbil’s BiG EYES seemed well-suited for use in batch processes,” says Hiroyuki Shiiya, Operation Engineer, Specialty Chemicals Group -2, Production Department -3, at the Niigata Plant of Mitsubishi Gas Chemical Company, Inc.

The group conducted a feasibility study*⁴ (hereafter referred to as FS) on three actual incidents where process problems had occurred, to verify BiG EYES’s ability to detect signs of anomalies as they moved towards full-scale implementation.

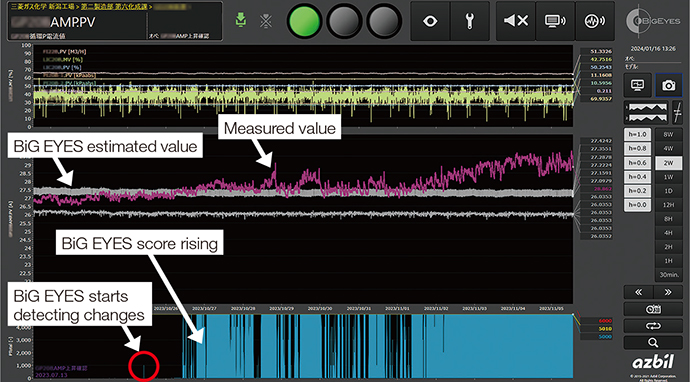

In the nylon polymerization tank, there was a challenge where a drop in the inlet temperature of the jacket used for heating the resin could lead to increased reaction times and cause quality defects. In response, the group trained BiG EYES on the normal process to verify whether it could detect early signs of anomalies using operational data from when anomalies occurred. As a result, it was confirmed that BiG EYES can detect these signs about one hour earlier than when operators would notice them through DCS alarms.

“When a DCS alarm goes off and we have to investigate the cause and address the problem, the quality of the resin continues to deteriorate. In contrast, as confirmed by the verification, BiG EYES detects the signs of anomalies about an hour earlier, allowing for early intervention and preventing deterioration of quality. Even just an hour is a significant improvement,” says Mr. Kato.

Similarly, a FS was conducted on issues such as clogging of the vent mesh in distillation columns and abnormal stoppage of vacuum pumps. For the vent mesh clogging, BiG EYES was able to detect signs about eight days before the operator noticed them, and for the abnormal stoppage of vacuum pumps, it detected them about one day in advance. Through the FS, it was confirmed that a system could be established to provide enough time for necessary countermeasures to be taken before situations like a deterioration in product quality or operational shutdowns occur.

Monitoring the current values of supply pumps with BiG EYES in the central control room

Equipment vent (supply air and exhaust ports). In the FS, BiG EYES detected process reaction abnormalities caused by clogged mesh filters attached to the vents approximately eight days before the operators did.

Beyond anomaly detection: Utilizing BiG EYES to visualize operational processes and know-how

Based on the results of this FS, Specialty Chemicals Group -2 decided to officially implement BiG EYES in December 2021 and began operation on the three targets where its effectiveness had been verified. Furthermore, the introduction of BiG EYES has led to early detection of new issues that are difficult to detect using only the DCS, such as clogged strainers and abnormal current values in raw material pumps. Particularly regarding the clogging of strainers, if a clog occurs and cleaning is not carried out immediately, it can lead to operational shutdown. However, since the equipment operates at high temperatures, it is preferable to avoid performing cleaning tasks when it is dark, such as nighttime. By using BiG EYES to detect early signs before a complete blockage occurs, operators can plan and decide whether to clean immediately after the current process ends or, in the case of night shifts, to continue operations until morning and perform inspections during daylight. This has significantly reduced the mental burden on operators, allowing them to act more strategically.

“We created around 15 models needed for the implementation of BiG EYES during the FS. We received training from Azbil on model creation in advance, and then created the models on-site while receiving advice from Azbil engineers,” says Mr. Shiiya.

In addition to detecting early signs of issues, they are using BiG EYES for various purposes, such as troubleshooting by comparing trends when reactions were favorable and when they were not, to investigate the causes. They also use it to evaluate the effectiveness of tank insulation, which incurs high construction costs, by comparing the outcomes with and without insulation.

“We aim to establish a system where the operators, who are directly involved in on-site operations, can play a central role in creating models to improve accuracy. As a result, we expect to see progress in visualizing operational processes and various types of know-how,” adds Mr. Shiiya.

The results achieved by using BiG EYES in Specialty Chemicals Group -2 have attracted attention within Mitsubishi Gas Chemical Company. At the company-wide improvement conference, the results were presented to the management, including the president, and were highly praised, earning the Production Technology Award. Furthermore, within the company, a BiG EYES user group has been established to share utilization methods between different plants and departments.

“After the improvement results were presented at the company-wide improvement conference, we heard many people from other departments expressing interest in trying it out. In the user group, we aim to promote the use of BiG EYES within the company by sharing information on improvement themes and model creation. We look forward to continued robust support from Azbil,” says Mr. Kato.

BiG EYES detects anomalies in the current of a circulation pump

*BiG EYES is a trademark of Azbil Corporation.

glossary

*¹ MX-Nylon

A material with excellent barrier properties against oxygen and carbon dioxide. It is used for a wide range of applications, including packaging materials, molding materials, and monofilaments.

*² Engineering plastics

A group of plastics with excellent strength and high heat resistance. In terms of operating temperature and strength, they occupy an intermediate or complimentary position between metal parts and traditional plastic parts, and are used according to the application.

*³ Distributed control system (DCS)

A dedicated system for monitoring and controlling the manufacturing processes and production equipment of plants and factories. To achieve an even distribution of load, the DCS manages the functions of each device over a network, resulting in safety and excellent maintainability.

*⁴ Feasibility study

Investigation and research conducted before starting a project to determine whether it is feasible. Also known as a feasibility analysis.

Learn about the customer

Manager

Specialty Chemicals Group -2

Production Dept. -3

Niigata Plant

Mitsubishi Gas Chemical Company, Inc.

Specialty Chemicals Group -2

Production Dept. -3

Niigata Plant

Mitsubishi Gas Chemical Company, Inc.

Mitsubishi Gas Chemical Company, Inc., Niigata Plant

- Location: 3500 Matsuhama-cho, Kita-ku, Niigata-city, Niigata

- Start of business operations: 1952

- Production content: Methanol and ammonia derivatives, meta xylenediamine, MX-Nylon, bio-related products

This article was translated from the Japanese version.

This article was published in June 2025.