Azbil Telstar, S.L.U.

Aiding pharmaceutical manufacturing processes, Azbil Telstar manufactures various types of equipment, one of which is an isolator system that maintains aseptic manufacturing and protects operators from harmful substances. The system is equipped with a micro flow rate liquid flowmeter that allows the amount of hydrogen peroxide solution sprayed in decontamination processes to be accurately measured. By measuring extremely small flow rates of 5–30 mL/min with high accuracy, the amount of spray can be optimized, improving the quality of the decontamination process.

Factories and Plants Other (Markets and Industries) Quality Control Overseas Flowmeters

Products/Services Provided

Obtaining an accurate grasp of minute amounts of hydrogen peroxide solution used for decontamination

Azbil Telstar, S.L.U., provides lyophilizers, sterilizers, water generation equipment for pharmaceutical use, steam generators, cleanroom equipment, and more for pharmaceutical plants, laboratories, and hospitals. The Spain-based company joined the azbil Group in January 2013, shouldering a portion of the Group’s Life Automation business and expanding the Group’s business globally with its bases in 16 European and Latin American countries. In addition to system development, manufacturing, and sales, the company provides consulting services for designing, engineering, and installing cleanrooms, and also for good manufacturing practices (GMPs). Utilizing comprehensive expertise and technology in the areas of pharmaceuticals, biotechnology, healthcare, and food and beverages, the company offers high value-added solutions for the whole life sciences area.

One type of product offered by Azbil Telstar is the isolator. Isolators provide an isolation unit where an aseptic environment can be maintained, and operators can be protected from harmful and toxic substances in pharmaceutical processes, and they are also used in facilities where COVID-19 vaccines are manufactured. The air pressure in the isolator’s housing can be raised (or lowered) so that the inside of the positive-pressure unit can be kept aseptic by preventing contaminants from entering. Operators do the necessary work within the isolator unit by inserting their hands into glove boxes built into the isolator housing. The housing must have a decontamination system, and Azbil Telstar provides one called ionHP+. “The ionHP+ system uniformly mixes a hydrogen peroxide solution and air to create a spray for surface decontamination. In the process we formerly used, the hydrogen peroxide solution was not directly monitored. Throughout a preliminary calibration process of the dosing system, a predetermined amount of hydrogen peroxide was injected into the volume. Meaning that the total sprayed hydrogen peroxide was indirectly estimated,” explains Ignacio Cantera, manager of the Pharmaceutical Research and Development Department.

In order to more accurately understand the amount of hydrogen peroxide solution used and improve the quality of the decontamination process, the company focused on measuring the actual flow rate. If the flow rate of the solution can be measured within the path to the spray port, the amount actually sprayed can be determined more accurately. As a result, the decontamination process can be improved by making adjustments depending on whether there is an excess or a shortage of the solution.

An isolator offered by Azbil Telstar. This piece of equipment ensures the safety of operators by providing an isolation unit where harmful and toxic substances can be processed.

High marks for highly accurate measurement of micro flow rates of 5–30 ml/min

The company began to consider introducing a liquid flowmeter into the system to improve the quality of ionHP+ sterilization around April 2018, and it decided to adopt Azbil Corporation’s micro flow rate liquid flowmeter (model F7M). “Azbil has an extensive track record for sensors and a broad product portfolio covering various solutions. For that reason, right from the beginning of our project for introducing a micro flow rate liquid flowmeter, we considered Azbil’s product as the most promising option,” says Mr. Cantera.

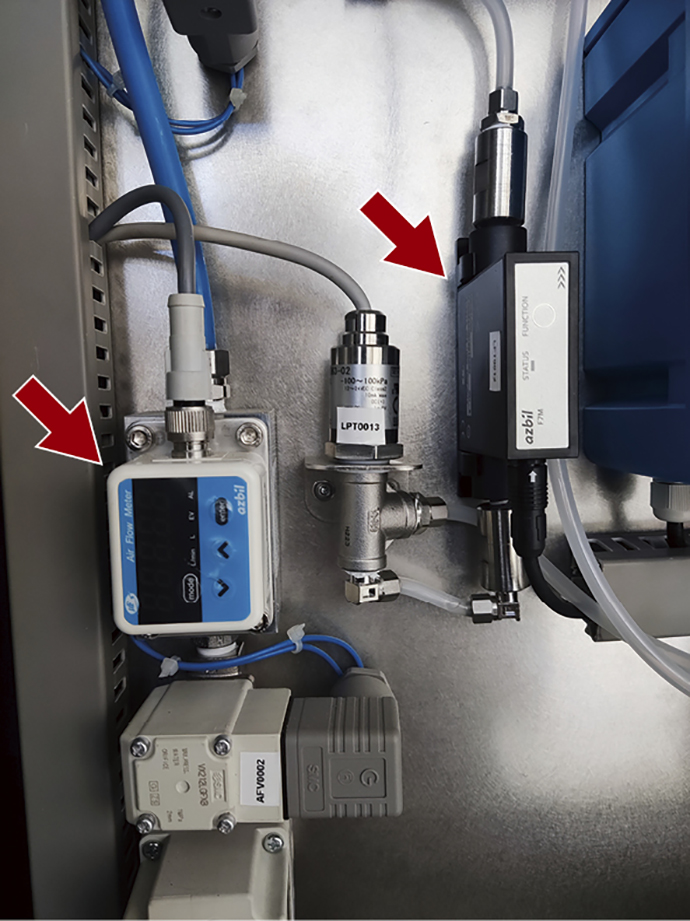

In July 2018, before introducing the flowmeter into products, Azbil Telstar began verification testing using an ionHP+ with an incorporated sample micro flow rate liquid flowmeter provided by Azbil. The testing found that the sensor’s repeatability was higher than initially expected, and it also confirmed the expected accuracy and high reliability of the product. “Liquid flowmeters on the market generally measure flow rates of 100 mL/min or more, but Azbil’s micro flow rate liquid flowmeter can measure a miniscule flow rate of several mL/min, which was previously difficult to do reliably. We greatly appreciate the fact that the flowmeter can measure with high accuracy very small flow rates of 5-30 mL/min, which is the range used by ionHP+,” comments Mr. Cantera.

In March 2019 Azbil Telstar provided the first isolator equipped with Azbil’s micro flow rate liquid flowmeter to a pharmaceutical company. Since then, all isolators provided by the company have had builtin micro flow rate liquid flowmeters. “An especially significant achievement was produced by the flowmeter’s function for estimating the thermal conductivity rate of the measured liquid during zero-point adjustment and automatically setting a corrected value. This makes adjustment work easier in the flow rate measurement of liquids like a hydrogen peroxide solution, whose concentration may vary at each site. A function like this cannot be found in other similar products, so it is an advantage of the micro flow rate liquid flowmeter that was achieved by Azbil’s advanced sensor technology,” says Mr. Cantera.

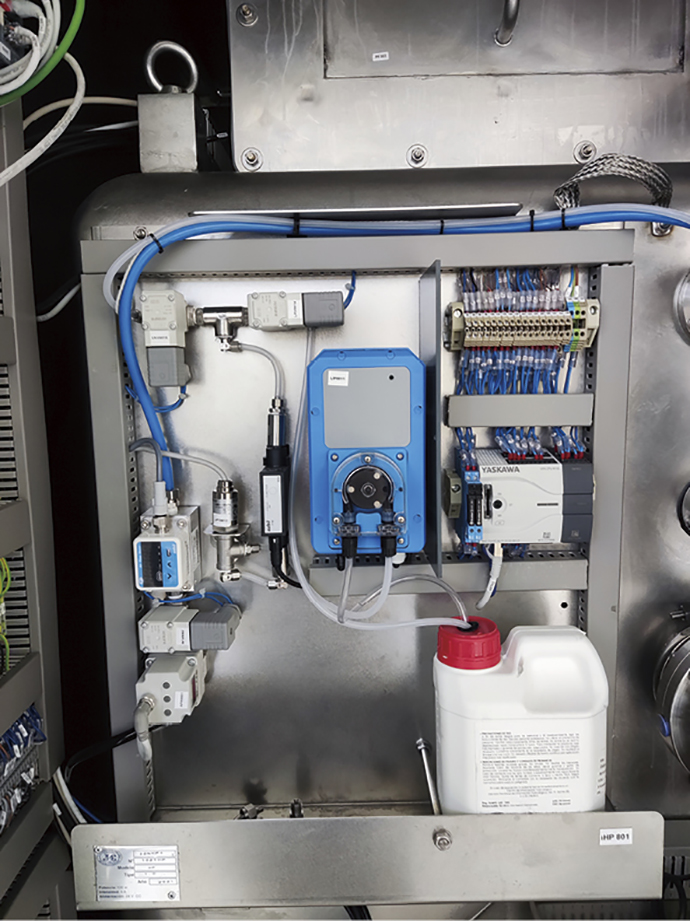

Azbil Telstar’s ionHP+ is installed in the isolator and sterilizes the interior of the housing using a hydrogen peroxide solution after completion of the process in the isolator.

Right: The micro flow rate liquid flowmeter (model F7M), which uses a thermal principle to measure out a micro flow of 20 ml/min of the hydrogen peroxide solution. Left: The air flowmeter, which uniformly mixes the solution and air for spraying.

Creating new value through collaborative development of technology

In addition, Azbil Telstar replaced two other components of ionHP+ with Azbil products: the gas flowmeter for uniform mixing of the hydrogen peroxide solution and air was replaced with Azbil’s air flowmeter and the sensor in the pipe for detecting the solution was replaced with Azbil’s pipe-mounted liquid-level switch with built-in amplifier. “The mixing ratio of gas and liquid is a very important key point. The pipe-mounted liquid-level switch is used to find air bubbles in the fluid pipeline. By utilizing these products, the amount of hydrogen peroxide solution we plan to inject is measured with high accuracy,” says Mr. Cantera. The company plans to use a wide range of Azbil components not only in isolators but also in various other systems it provides.

Azbil Telstar has expanded its production in Spain and the United Kingdom, and now plans to establish a larger and more advanced production base in Shanghai, China, to meet the growing need for its products. “For the technology-oriented Telstar Group, Azbil is a reliable partner, since we aim to provide better customer-oriented products and solutions to the global market while continuously strengthening re- An isolator offered by Azbil Telstar. This piece of equipment ensures the safety of operators by providing an isolation unit where harmful and toxic substances can be processed. Azbil Telstar’s ionHP+ is installed in the isolator and sterilizes the interior of the housing using a hydrogen peroxide solution after completion of the process in the isolator. Right: The micro flow rate liquid flowmeter (model F7M), which uses a thermal principle to measure out a micro flow of 20 ml/min of the hydrogen peroxide solution. Left: The air flowmeter, which uniformly mixes the solution and air for spraying. Azbil Telstar, S.L.U. Ignacio Cantera Manager Pharmaceutical Research and Development Department Av. Font i Sagué 55, Parc Cientific i Tecnològic Orbital 40, 08227, Terrassa, Spain Location 1963 Established Development, manufacture, and sale of manufacturing equipment and environmental equipment for pharmaceutical plants, laboratories, and hospitals; and consulting and engineering related to cleanrooms Business search and development. For example, we have already started working on new technology and equipment development in collaboration with Azbil’s R&D department.

Through such collaboration, we can continue to provide new value to our customers and to society,” says Mr. Cantera.

Learn about the customer

Manager

Pharmaceutical Research and Development Department

Azbil Telstar, S.L.U.

Azbil Telstar, S.L.U.

- Location: Av. Font i Sagué 55, Parc Cientific i Tecnològic Orbital 40, 08227, Terrassa, Spain

- Established: 1963

- Business: Development, manufacture, and sale of manufacturing equipment and environmental equipment for pharmaceutical plants, laboratories, and hospitals; and consulting and engineering related to cleanrooms

This article was published in September 2022.