Fujisawa District, Ebara Corporation

Ebara Corporation’s Fujisawa District develops and manufactures dry vacuum pumps that play a vital role in semiconductor production processes. To support the efficient operation of semiconductor plants, Ebara adopted a regulator block proposed by Azbil TA Co., Ltd. for the dry vacuum pumps, which are required to be compact. This led not only to the successful downsizing of the product but also a significant reduction in production lead time and lower manufacturing costs.

Factories and Plants Semiconductors Cost Reduction Control Valves and Actuators

Reducing the footprint of component products is key to enhancing semiconductor productivity

Since its founding in 1912, Ebara Corporation has supported evolving industries, social infrastructure, and the advancing information society with technologies that create waves of innovation in the water, air, electronics, and energy sectors. The company has developed and supplied a wide range of products such as pumps, fans, and chillers, many of which were the first of their kind to be produced in Japan. Today, under a structure consisting of the Building Service & Industrial Company, Energy Company, Infrastructure Company, Environmental Solutions Company, and Precision Machinery Company, Ebara provides products and services essential for daily life and industries both in Japan and overseas, while contributing to the resolution of social issues and the preservation and improvement of the global environment.

In recent years, the Precision Machinery Company has achieved remarkable growth. The Company offers a variety of products essential for advanced semiconductor manufacturing, including dry vacuum pumps, chemical mechanical polishing (CMP) equipment for wafer polishing, exhaust abatement systems, and ozonized water generators. Of these, the dry vacuum pumps and CMP systems hold a leading share in the global market and contribute greatly to the manufacture and advancement of semiconductors.

“In addition to developing dry vacuum pumps for which demand is expected to grow further, the Fujisawa District also serves as an important production base, supporting the continued success of the Precision Machinery Company,” says Masaru Yonekura of the Corporate Synergy Creation Section, Strategy and Promotion Department, Management Strategy Control Division, Precision Machinery Company, Ebara Corporation.

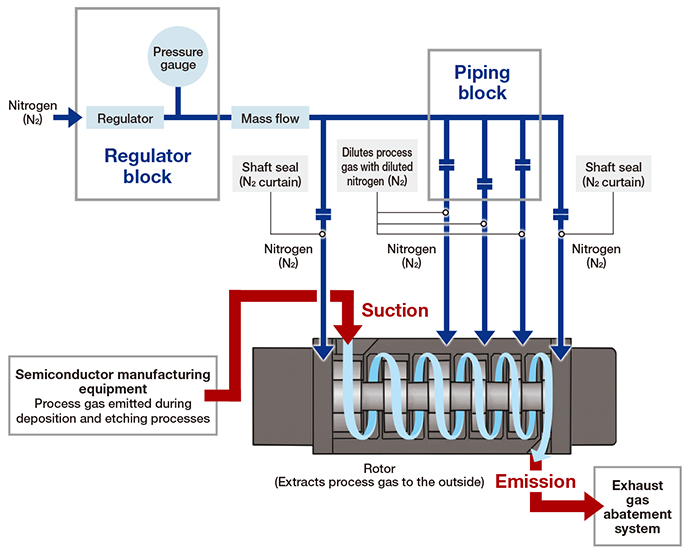

Semiconductors are manufactured inside a vacuum chamber within the semiconductor manufacturing equipment, where processes such as deposition and etching take place. Dry vacuum pumps are essential for maintaining the clean vacuum environment required for these processes. The Fujisawa District has incorporated individual components such as regulators and pressure gauges supplied by Azbil TA into the mechanism that creates the vacuum environment and exhausts process gases to treatment systems.

In the semiconductor manufacturing field, the miniaturization of transistors used for amplifying and switching signals is regarded as a key differentiator for improving performance, and competition among manufacturers to advance this miniaturization is intensifying each year. The miniaturization of semiconductors has made the semiconductor manufacturing process even more complex, leading to a rise in both the variety and number of semiconductor manufacturing equipment. Consequently, more dry vacuum pumps are needed to support the operation of these tools. At the same time, semiconductor factories must install dry vacuum pumps and other components within limited space to boost productivity, making it important to downsize equipment and improve spatial efficiency.

“How to efficiently install more vacuum pumps and other equipment in semiconductor factories has become a major challenge for manufacturers, and our dry vacuum pumps also needed to be more compact and space-saving in design,” explains Seiji Shimada of the Development Section, Vacuum Products Engineering Department, Component Division, Precision Machinery Company, Ebara Corporation.

Regulators, pressure gauges, and other components modularized into a block and customized for each product

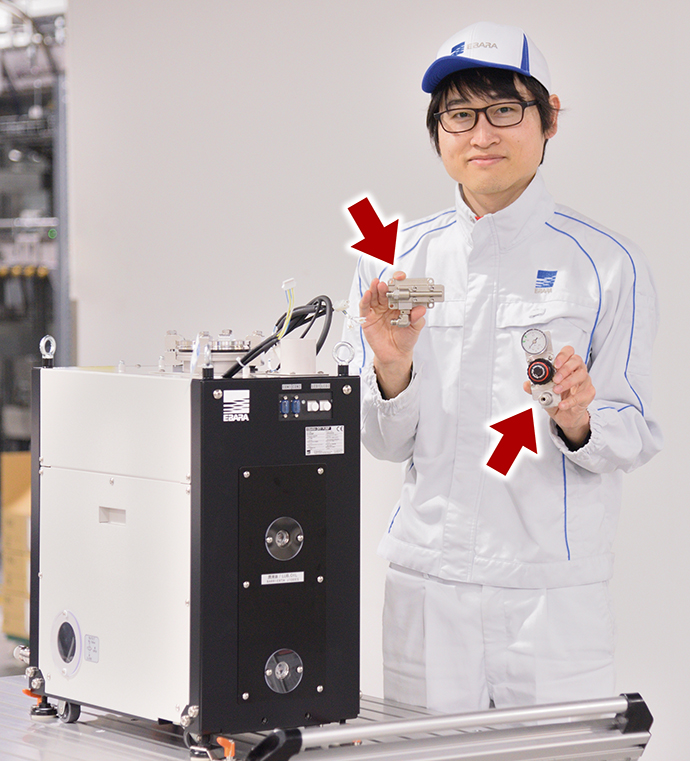

Regulator block (right) and piping block (left) incorporated into the energy-efficient, space-saving Model EV-S Dry Vacuum Pump

In response to this situation, in 2008 Azbil TA proposed a solution tailored to the specifications of the Fujisawa District's dry vacuum pumps: integrating and modularizing components such as regulators and pressure gauges, which had previously been installed individually, and providing them as a single block.

“We thought that if Azbil TA’s proposal could be realized, it would improve the feasibility of downsizing our products. It would also eliminate the need to assemble regulators and pressure gauges individually, shorten production lead times, and reduce costs. We also saw benefits such as lower risk of gas leakage from piping connections,” explains Mr. Shimada.

Together with Azbil TA, the Fujisawa District conducted a series of detailed studies on the position and method of assembling the regulator block to the dry vacuum pump, as well as the shape and materials of the block, taking into account cost considerations.

“Azbil TA listened carefully to our detailed requirements, such as the needle valve tension and the block on which it is installed, and worked closely with us over an extended period to fine-tune the design and bring the product to completion,” notes Daisuke Takeuchi of the Products Planning Section, Business Strategy and Planning Department, Components Division, Precision Machinery Company, Ebara Corporation.

As a result, the regulator block was successfully installed in the Model ESR Dry Vacuum Pump, which Ebara has been offering since 2003. Since then, Azbil TA’s regulator blocks have also been adopted in models such as the EV-S and EV-X, which feature energy efficiency and a compact design.

Structure around the regulator block inside the dry vacuum pump

Installing the regulator block contributes to production efficiency

These initiatives have delivered the expected results for Ebara. First, the miniaturization of the dry vacuum pumps has enhanced the competitiveness of its products among customers seeking semiconductor miniaturization along with energy and space savings. In addition, eliminating the need to assemble regulators and pressure gauges on the product or perform piping work has shortened production lead times, thereby contributing to lower production costs.

“At Building V7, where many processes for dry vacuum pumps have been automated, efforts to improve productivity are ongoing. The newly developed regulator, which integrates multiple components, has not only contributed to space savings but also improved efficiency and reduced lead times in production. I believe this has been a highly meaningful achievement,” comments Mr. Yonekura.

Ebara will continue meeting the needs of semiconductor manufacturers by supplying dry vacuum pumps equipped with Azbil TA’s regulator blocks. To meet the demand for further space saving and streamlining at production sites, they also plan to work with Azbil TA to explore cost reductions through refinements to the regulator block’s shape and materials, as well as the integration of surrounding equipment.

“We, Precision Machinery Company, have begun discussions on linking with centralized monitoring systems to automate the entire sub-fab*1 area that supports cleanroom operations—including equipment like dry vacuum pumps and chillers—and to enable predictive maintenance. For this initiative, we are looking into the possibility of collaborating with the azbil Group, including Azbil TA, which has extensive experience and deep expertise in control systems,” says Mr. Takeuchi.

glossary

*1 Sub-fab

A “fab” refers to a factory that mass-produces semiconductor products. A sub-fab houses numerous vacuum pumps, gas abatement units, and other equipment that support semiconductor manufacturing. These help maintain the clean environment required for the processes of cleanroom equipment and treat the exhaust gases and byproducts generated during production.

Learn about the customer

Corporate Synergy Creation Section, Strategy and Promotion Department

Management Strategy Control Division

Precision Machinery Company

Ebara Corporation, Fujisawa District

Products Planning Section, Business Strategy and Planning Department

Components Division

Precision Machinery Company

Ebara Corporation, Fujisawa District

Development Section, Vacuum Products Engineering Department

Components Division

Precision Machinery Company

Ebara Corporation, Fujisawa District

Fujisawa District, Ebara Corporation

- Location: 4-2-1 Hon-Fujisawa, Fujisawa City, Kanagawa Prefecture

- Start of operations: July 1965

- Business activities: Development, processing, manufacturing, and assembly of standard pumps, custom pumps, and dry vacuum pumps

This article was translated from Japanese version.

This article was published in August 2025.