Shizuoka City’s Nishigaya Incineration Plant

The Nishigaya Incineration Plant in Shizuoka City reprocesses household waste collected in the region through high temperature melting, and also functions as a power plant by using the gas generated during the melting process to produce electricity. At the plant, adjusting the temperature in the heat utilization process for power generation placed a heavy burden on personnel. But after the introduction of smart valve positioners related to control, they are able to visualize the status of the control valves and utilize operation data for control adjustments. This makes it possible to stabilize the highly fluctuating temperatures. As a result, power generation efficiency has also been improved.

Factories and Plants Other (Markets and Industries) Reliable Operation Operation Improvement Maintenance Support Cloud, IoT, and AI Industrial Automation Control and Monitoring Systems and Software

Products/Services Provided

Adjusting the widely fluctuating temperatures in the power generation process became a challenge

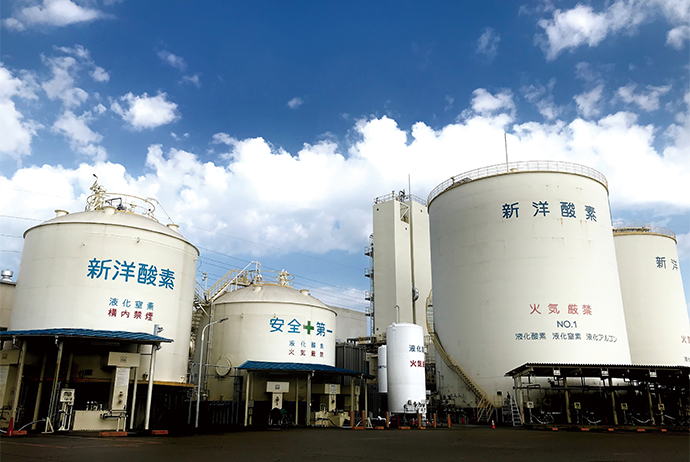

Shizuoka City, in Shizuoka Prefecture, is in the central region of Japan. The Nishigaya Incineration Plant, located in the city’s Aoi Ward, primarily accepts waste from households in the southwestern part of the city and processes it through high temperature melting to promote waste recycling. Additionally, it serves as a local production and consumption power plant by reusing exhaust gas produced during waste processing to generate electricity, which is then supplied to municipal facilities.

“Regarding waste recycling, we have been working on a research project in collaboration with industry, academia, and government to recycle molten slag*¹—the sand-like waste generated during the waste processing—into agricultural fertilizer. In March 2022, the quality of this product was recognized by Japan’s Ministry of Agriculture, Forestry and Fisheries, and it was officially registered as an agricultural fertilizer for the first time nationwide,” says Takenori Yamamoto, Plant Manager of the Nishigaya Incineration Plant, from the Waste Disposal Section of the Shizuoka City Environmental Bureau.

The Nishigaya Incineration Plant, undertaking innovative initiatives, is actively working to improve its operations. As part of these efforts, the plant has aimed to enhance the control of the heat utilization process in power generation. When waste is processed through high temperature melting in the gasification melting furnace, the pyrolysis gas produced is burned, and the heat is recovered by a boiler to generate steam at approximately 400°C, which drives a turbine to produce electricity. This boiler is required to undergo inspections every two years as mandated by Japan’s Electricity Business Act. However, in emergency situations, such as a disaster, the inspection period can be extended by up to three months. If the temperature exceeds the specified limit by more than 28°C even once during normal operations, though, the option to extend the inspection period will be lost.

“We use the DCS*² to maintain a temperature of 400°C, but large temperature fluctuations, caused by the inherent variability of waste in treatment facilities, are unavoidable. There were many instances where PID control*³ struggled to keep up with the set values, so operators constantly monitored the temperature control of the superheater to keep the boiler temperature from exceeding 428°C, intervening manually to adjust the temperature. In addition to the human workload, there was also a high load on the control valves involved in the process. Furthermore, the temperature fluctuations were also a factor in reducing power generation efficiency,” says Mr. Yamamoto.

Confirmed that temperature stability improved by replacing existing positioners with electronic ones

In response, Shizuoka City consulted Nippon Steel Environmental & Energy Solutions Corporation, which is entrusted with operating the plant. They proposed using Azbil Corporation’s electronic smart valve positioners as well as the control valve maintenance support system, PLUG-IN Valstaff (hereafter Valstaff), which monitors the condition and operation of each control valve in real time and reflects this information in the control process.

“At Nippon Steel Environmental & Energy Solutions, we had been experimentally operating Azbil’s positioners and Valstaff at multiple sites to explore the possibility of utilizing control valve operation data in the control process. When Shizuoka City approached us, its effectiveness was just becoming clear, and we believed it could solve their issues. So, we proposed a six-month trial implementation,” says Ryuichi Kawano, from the Equipment Technology Office, Equipment Management Department, at Nippon Steel Environmental & Energy Solutions Corporation.

As a result of the trial operation, it was confirmed that simply using Azbil’s positioners significantly improved temperature fluctuations.

“The introduction of the smart valve positioner has enhanced the control valves’ responsiveness to commands from the DCS, confirming their ability to respond quickly and effectively. As a result, the temperature fluctuations that burdened the operators have almost been eliminated,” says Shinichiro Izumi, Director of the Shizuoka Business Office of the Chubu Branch Office, at Nippon Steel Environmental & Energy Solutions Corporation.

In response, the Nishigaya Incineration Plant decided in December 2023 to fully introduce five smart valve positioners and Valstaff, focusing on the main steam system of the power generation process, in which temperature is difficult to control.

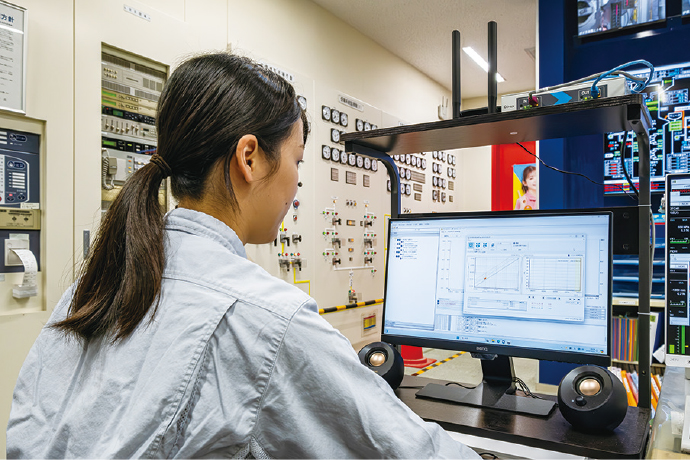

On the Valstaff screen, the stick-slip*⁵ diagnostic parameters of the main steam temperature control valve can be checked in a graph

Reduce maintenance costs by implementing maintenance based on the condition of the control valves

The Nishigaya Incineration Plant is achieving results beyond expectations with the full-scale implementation. “Before the implementation, operators needed to manually adjust the temperature several times an hour, but now it is operated with only a few preventive adjustments a day,” says Mr. Yamamoto.

Not only has the operators’ workload been reduced, but the suppression of temperature fluctuations has also led to improved power generation efficiency. Furthermore, Valstaff’s visualization of each control valve’s operational status has greatly aided in reviewing PID control and other processes.

“Even when changing set values in the DCS, we can determine the suitability of the PID control variables from the control valve data visualized by Valstaff. This has enabled the quick application of the appropriate values to the control, preventing temperature fluctuations,” explains Yuka Motomatsu from the Operations Technology Office in the Operations Technology Department at Nippon Steel Environmental & Energy Solutions Corporation.

In addition to Valstaff, Shizuoka City has installed the Dx*⁴ Valve Cloud Service, which allows users to check the diagnostic results for the control valves online. This has made it possible to understand the health of any control valve at any time. This information will be utilized in future maintenance planning.

"It has also become easier to plan overhaul implementation and budgets. At our plant, we conduct regular inspections and repairs every year, and have been performing open inspections, in which the control valves are disassembled and inspected, on a cycle of once every two years. However, in reality, many of the control valves are found to have no problems when disassembled. From now on, we will be able to conduct open inspections at the appropriate timing based on the information obtained from Valstaff. In other words, it is now possible to shift from time-based maintenance (TBM), where maintenance is performed regularly regardless of whether there are problems, to condition-based maintenance (CBM), where maintenance is conducted according to the state of deterioration, which is expected to reduce costs,” says Mr. Yamamoto.

At the Nishigaya Incineration Plant, there are also plans to deploy a similar system in the melting and burning process in the future, aiming to achieve control that optimizes energy use.

“We have high expectations that Azbil will continue enhancing the added value of its products and services, such as by increasing the variety of control valves that can be equipped with smart valve positioners,” says Mr. Kawano.

A smart valve positioner installed on another company’s control valve, which regulates temperature by injecting water into the steam used to turn power generation turbines

※Valstaff is a trademark of Azbil Corporation in Japan.

glossary

*1. Molten slag

A glass-like product obtained by melting waste in a furnace maintained at a high temperature of approximately 1700 degrees or more, and then cooling and solidifying it in air or water.

*2. Distributed control system (DCS)

A dedicated system for monitoring and controlling the manufacturing processes and production equipment of plants and factories.

*3. PID control

A basic feedback control method that controls input values using three elements: the deviation between the output value and the target value, its integral, and the derivative.

*4. Dx

An abbreviation for diagnosis in the field of medicine. Azbil uses this phrase to express that the service enables customers to always use their valves safely by understanding their condition.

*5. Stick-slip

A phenomenon where the valve stem repeatedly sticks and suddenly slips.

Learn about the customer

Plant Manager

Nishigaya Incineration Plant

Waste Disposal Section

Shizuoka City Environmental Bureau

Equipment Technology Office

Equipment Management Department

Nippon Steel Environmental & Energy Solutions Corporation

Operations Technology Office

Operations Technology Department

Nippon Steel Environmental & Energy Solutions Corporation

Director

Shizuoka Business Office

Chubu Branch Office

Nippon Steel Environmental & Energy Solutions Corporation

Shizuoka City’s Nishigaya Incineration Plant

Shizuoka City’s Nishigaya Incineration Plant

- Location: 553 Nishigaya, Aoi-ku, Shizuoka City, Shizuoka Prefecture

- Completion: March 2010

- Operations: Waste melting, recycling, and power generation

Nippon Steel Environmental & Energy Solutions Corporation

- Location: 46-59 Oaza Nakahara, Tobata-ku, Kitakyushu City, Fukuoka Prefecture

- Founded: April 1994

- Business activities: Operation and management of waste treatment facilities, recycling facilities, and other environmental facilities

This article was translated from the Japanese version.

This article was published in March 2025.