savic-net FX mini Building Management System

Osaka Municipal Central Wholesale Market (Honjo Market)

The Osaka Municipal Central Wholesale Market, also known as the Honjo (Central) Market, serves as Osaka’s “kitchen,” supporting the eating habits of residents. It is a center for collecting, distributing, and trading vegetables, fruit, and marine products. Recently Azbil upgraded the cooling towers for the aging freezers and refrigerators at the market, as well as the equipment for the HVAC system, using an ESCO business model. Thanks to a variety of measures that went beyond mere upgrading of the equipment, Azbil provided significant energy savings, greatly exceeding the initial targets.

Building Solutions Other (Markets and Industries) Energy Efficiency Countermeasures for Aging Building Management Systems Building Energy Management

Products/Services Provided

Aiming for energy savings for the entire market using an ESCO plan to upgrade cooling towers and HVAC equipment

The Osaka Municipal Central Wholesale Market opened in its present location, Noda in Fukushima Ward, in November 1931 and was the largest general market in Asia at that time. Since then, together with the Tobu (East) Market, which opened in Higashi-Sumiyoshi Ward in 1964 to respond to the increased business that accompanied the rapid growth of the Japanese economy, the Honjo Market has supported the eating habits of Osaka-ites as the city’s “kitchen,” handling vegetables, fruit, and marine products. At present, over 260 billion yen changes hands there every year, making it the third largest market in Japan (after the Toyosu Market and Ota Market).

It is widely known that Osaka, which operates the market, has pioneered energy conservation measures at public facilities using an ESCO business model* ahead of other local governments in Japan. Starting with the Osaka City General Hospital in 2005, the ESCO business model has been used at several facilities, including city offices, sports facilities, research institutes, and museums.

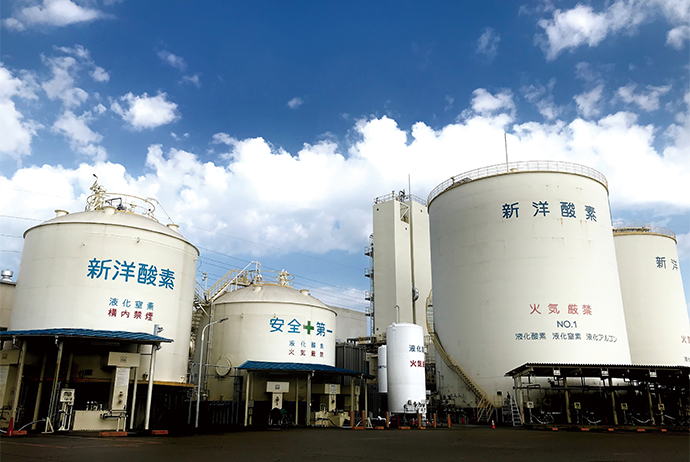

“At the Honjo Market, the cooling towers for the freezers and refrigerators, and the hot and chilled water generating equipment for the HVAC system, had been operating for more than 20 years, and their age had become noticeable. As part of the ESCO project, we decided to upgrade to more efficient models in order to save energy,” explains Honjo Deputy Director Isao Fujii.

For this purpose, the city of Osaka established requirements for developing an ESCO project, which was to continue for a maximum of 15 years from fiscal 2018, and ran a public tender in June of 2016. In the competition, which was judged by private experts, Azbil Corporation was selected as the best supplier based on its proposal of a 10% or more energy savings rate target for the entire market, utilizing business support subsidies that are available for reducing energy consumption.

“The selection process assessed specific effects, such as the reduction of energy use and of carbon dioxide (CO2) emissions, as well as details on the results of the ESCO project, proposed innovations, construction plans, and the maintenance regime afterwards. The suppliers were scored on these points, and Azbil’s proposal came out with the highest overall rating,” says Honjo Subsection Manager Junji Nakajima.

Avoiding disturbances to the market’s daily operations with careful preparation and planning for construction

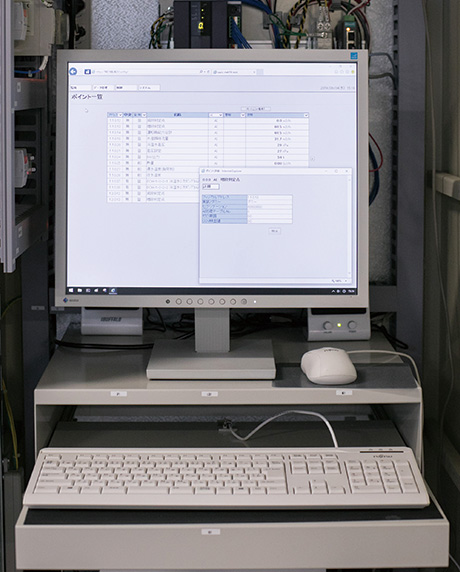

Azbil’s building automation system for small and medium sized facilities installed in an air-conditioning control panel.

Subsequently, a business subsidy project to reduce energy use was adopted in August 2017, and construction began in September. The main elements of the project were the replacement of aging cooling towers for the freezers and refrigerators and replacement of the HVAC system’s hot and chilled water generators with high-efficiency aircooled heat-pump chillers. In addition to installing variable speed drive units for the air supply/exhaust fans, Azbil provided LED lighting to replace the inefficient mercury and fluorescent lamps.

Azbil also introduced its building automation system for small- and medium-sized facilities. This system is connected to Azbil’s Dataware Center via the Internet so that Azbil can appropriately manage energy consumption trends at the market.

In the construction phase, Azbil followed a construction plan that did not disturb the wholesalers or other operations at the market. “For example,” explains Mr. Nakajima, “the most important pieces of equipment at the market are the freezers and refrigerators that keep the food fresh—and at Honjo Market, we have some 500 freezers and refrigerators. They range in size from large units that are shared to small ones installed in individual stores. The key issue for the project was how to upgrade the cooling towers, which are indispensable for the operation of these freezers and refrigerators, without affecting daily operations.”

All the freezers and refrigerators in the market are connected to the cooling towers by piping. Azbil devised a method whereby bypass piping installed between the two cooling towers and the freezers/refrigerators was utilized so that each cooling tower could substitute for the other one. This method was adopted during construction, allowing the equipment to be replaced without stopping the operation of the freezers and refrigerators. While one of the cooling towers was stopped for upgrade work, the other one continued operating, and when upgrade of the first one was completed, the bypass valve was switched and the other cooling tower was upgraded. This allowed the replacement to be completed without interrupting the freezers and refrigerators or otherwise disturbing market operations.

“Before the actual upgrade,” continues Mr. Nakajima, “we carried out a large-scale operation verification test in which we switched the bypass valve. We also took steps such as checking the volume of water and measuring how the cooling water temperature changed before starting construction. As a result, we were fully prepared for the cooling tower upgrade, and we completed the actual work without any problems. We were able to effectively take advantage of Azbil’s expertise in air-conditioning and HVAC control.”

“We anticipated that it would be difficult to install the LED lights in the market since we needed to install 6,000 units using aerial work platforms,” adds Mr. Fujii. “Again, in cooperation with Azbil, we worked closely with market stakeholders in advance and followed a detailed construction plan. As a result, we were able to convert all the lights within the project scope to LEDs in just three months. I think Azbil did a great job in achieving this in such a short period of time.”

Cooling towers for freezers and refrigerators on the roof of the market.

Air-cooled heat pump chillers for the HVAC system. With a unified and redundant design, backup operation is possible in the event of a failure, providing security as well as energy savings.

An early-morning auction. Approximately 6,000 mercury and fluorescent lamps used in the market were converted to LEDs.

Significant energy savings achieved, far exceeding initial goals

As a result of the upgrade, Azbil delivered significant energy savings at the Honjo Market. For equipment within the scope of the ESCO project, the target CO2 reduction rate proposed by Azbil in the public tender was about 20.34%, equivalent to about 1106 kl/year of crude oil. But after one year, the results far surpassed that figure. Furthermore, on a monetary basis the project exceeded the planned reduction by 23%.

“Going forward, we expect to see various changes in the business environment, such as an increase in the number of vendors entering and exiting the market, and it is important for us to figure out how to achieve even greater energy savings in spite of these changes. Our contract with Azbil lasts for 15 years, and over that time, we expect that Azbil will continue to support our efforts and provide advice on how we can fine-tune and improve the operation of our equipment,” says Mr. Fujii.

glossary

Energy Services Company (ESCO) business model

A business model in which a service provider guarantees the effectiveness of comprehensive services related to energy savings in factories and office buildings. There are two types of ESCO contract: a “guaranteed-savings contract” in which the customer provides collateral for the investment and acts as guarantor, and a “shared-savings contract” in which the ESCO company provides all the investment and the customer does not have to act as guarantor.

Learn about the customer

Honjo Deputy Director /

Acting Manager in charge of

equipment and facilities

Honjo Subsection Manager /

Central Market Subsection

Manager (for Mechanical

Facilities)

Osaka Municipal Central Wholesale Market (Honjo Market)

Osaka Municipal Central Wholesale Market (Honjo Market)

- Location: 1-1-86 Noda, Fukushima-ku, Osaka-shi, Osaka

- Opened: November 1931

- Business: Collection, distribution, pricing, and sale of vegetables, fruit, and marine products

This case study was published in the 2020 No.3 issue of the azbil Group's corporate magazine, azbil.