Narita International Airport Central Heating and Cooling Plant

At Narita International Airport, a central heating and cooling plant provides chilled and hot water for air conditioning and heating to about 50 facilities inside the airport. As part of its ongoing efforts to conserve energy, Narita International Airport initiated an energy service company (ESCO) project to introduce a system that would ensure optimal heat source operation. The system, which provides guidance for optimally starting and stopping various heat source equipment based on the demand projections calculated from weather information, has resulted in energy cost savings far exceeding the targets.

Building Solutions Airports Energy Efficiency Energy Management Cost Reduction Building Energy Management

Products/Services Provided

Energy Conservation at the Plant Providing Chilled and Hot Water to Airport Facilities

The monitoring room of the airport’s central heating and cooling plant, where Advanced-PS and the utility optimization software package are installed.

Narita International Airport is a hub airport and, for international travelers, a representative of Japan. Since the number of inbound tourists has rapidly increased in recent years, Narita’s presence as an air gateway welcoming international passengers to Japan has also increased.

Since the airport opened in 1978, it has been working on measures to lessen the local environmental impact caused by the airport’s operation and to help preserve the Earth’s environment and contribute to establishing a sustainable society.

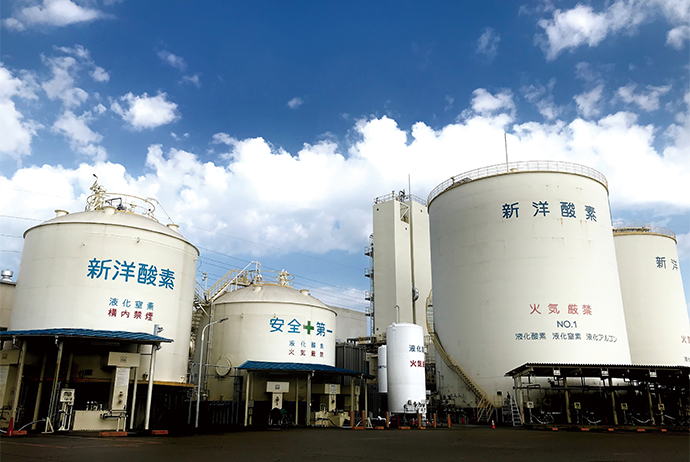

“In recent years, we have been searching for a way to reduce the energy of the central heating and cooling plant, which is a large energy plant providing chilled and hot water for air conditioning and heating to about 50 facilities located in the airport, such as passenger terminals, cargo buildings, etc.,” explains Akira Kondo, a manager in the Facilities Management Department of Narita International Airport Corporation.

“We had already introduced energy-saving equipment and cogeneration technology along with operational changes, but more drastic measures were needed to achieve further energy savings,” adds Tetsuya Yamamoto, a section manager in the Mechanical Systems Department of Narita Airport Facilities Corporation.

Dramatic Reduction of Heat Production Costs without Decreasing Heat Supply

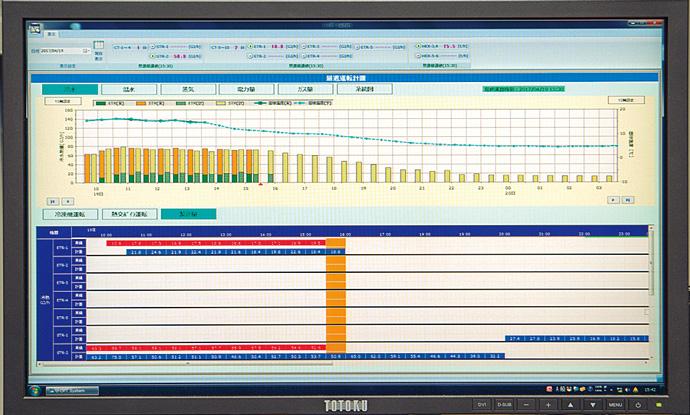

The utility optimization software package determines when to start and stop the heat source equipment by making calculations based on weather forecast data. It also shows predicted and measured temperature values, and charts of the planned and measured amounts of heat production.

It was Azbil Corporation, early in 2012, that proposed a way to save energy at the central heating and cooling plant. According to the proposal, adding a utility optimization software package to Advanced-PS™, which is used as the DCS 1 for monitoring and controlling the heat source equipment, would provide heat production cost savings without decreasing the heat quantity supplied from the central heating and cooling plant to each facility.

“A general energy-saving measure to decrease the heat supply to each facility would have an impact on the comfort of customers and employees,” comments Mr. Kondo. “In this respect, Azbil’s proposal, which would raise heat production efficiency without changing the supplied heat quantity, made good sense for our facility management.”

“Azbil’s proposal allowed us to use the existing monitoring and control system so that large-scale upgrade work was not required, which we valued as well,” adds Shugo Ohba of the Facilities Management Department. “Furthermore, it was an ESCO project. 2 For that reason it did not require a large initial investment, but achievement of the preset target was guaranteed, which was a big attraction for us because we could minimize the investment risk.”

Narita International Airport adopted Azbil’s proposal and introduced the utility optimization software package to the existing facilities in 2013. In April 2014, service began based on the 5-year ESCO contract.

Cost Minimized by Guidance for Optimized Starting and Stopping of Individual Heat Source Units

A substantial portion of the passenger terminals at the airport is covered with glass, and therefore the heating load or cooling load needed for heating or air conditioning depends on the weather. The main goal of the utility optimization software package is to calculate the demand for chilled and/or hot water for air conditioning and heating based on external weather forecast services. The utility optimization software package predicts the energy needs in half-hour periods for up to 24 hours based on the latest weather information, which is updated every 60 minutes, and provides operators with guidance on which heat source equipment in the central heating and cooling plant to select—for example, whether to use an electric or a gas unit—and when to start or stop the equipment. Taking into consideration the unit cost of energy, which changes every month, it supports heat supply operation by a best mix of equipment, electricity and gas, to minimize the cost at each moment.

“In the past, operators started or stopped the heat equipment at their discretion, based on the weather that day or the temperature on the previous day. But after installing the utility optimization software package, we were able to start or stop the equipment on a more optimal and detailed timeline. For example, we previously started the equipment with a margin of 1 hour, but the software guidance shortened that to 30 minutes. Small amounts of cost savings can lead to a big result,” says Mr. Yamamoto.

Additionally, according to Eiichi Shimada, a chief engineer for the Mechanical Systems Department, “Since the start of operations, we have shared with Azbil the advice given by the utility optimization software package, along with the actual operational status of the site’s facilities. Based on that information, Azbil has tuned the system and increased the accuracy of the advice.”

Final decisions on starting or stopping the plant equipment are made by a frontline operator. Through the past 3 years of system operation, onsite know-how accumulated by the operators, combined with the knowledge that Azbil has incorporated into the utility optimization software package, has taken the cost-efficient operation of the system to a higher level.

The target preset for energy cost reduction was achieved in the very first fiscal year. Furthermore, an unexpected level of improvement, 140% of the target, was reached in the 2nd and the 3rd fiscal years, which was the equivalent of about a 700 ton reduction of CO2 emissions per year. The energy-saving project helped the environment as well as producing savings.

“At trimonthly meetings, Azbil reports to us in an easy-to-understand way about the results from the utility optimization software package. Additionally, we appreciate Azbil’s support in resolving problems that occur on the site, and its positive efforts to provide us with information and know-how on energy-efficiency in general,” comments Masato Hagiwara of the Facilities Management Department. “We would also like Azbil to deliver not only help with further energy cost reduction, but also proposals for energy-saving measures from a broader perspective, beyond the framework of the measures taken this time,” says Mr. Kondo.

An electric chiller in the central heating and cooling plant.

A two-drum water tube steam boiler.

* Advanced-PS is a trademark of Azbil Corporation.

glossary

*1 DCS (Distributed Control System)

A system that monitors and controls the manufacturing process or production facilities in plants and factories. To achieve even distribution of load, the DCS distributes the functions of each device over a network, resulting in safety and excellent maintainability.

*2 ESCO (Energy Service COmpany) project

A project in which an energy service company guarantees a certain level of energy savings through the provision of comprehensive services for the reduction of energy consumption in a factory or building. There are two types of contract.

Guaranteed-savings contract: The facility owner bears the project costs and the energy service company guarantees the energy savings.

Shared-savings contract: The energy service company bears the project costs and the customer pays a fee for the energy savings and other services.

Learn about the customer

Manager, Mechanical Systems

Facilities Management Department

Airport Operations Division

Narita International Airport Corporation

Mechanical Systems

Facilities Management Department

Airport Operations Division

Narita International Airport Corporation

Mechanical Systems

Facilities Management Department

Airport Operations Division

Narita International Airport Corporation

Section Manager

Cooling and Heating Energy Supply Section

Mechanical Systems Department

NARITA AIRPORT FACILITIES CORPORATION(NAFCO)

Chief Engineer

Cooling and Heating Energy Supply Section

Mechanical Systems Department

NARITA AIRPORT FACILITIES CORPORATION(NAFCO)

Narita International Airport Central Heating and Cooling Plant

Narita International Airport Corporation

- Address: NAA-Bldg., Narita International Airport, Narita, Chiba Prefecture

- Establishment: July 30, 1966 (New Tokyo International Airport Authority)

April 1, 2004 (Narita International Airport Corporation) - Business profile: Management of Narita International Airport, retailing such as operating shops and other facilities, facility leasing, railway service

This case study was published in the 2018 Vol.3 issue of the azbil Group's corporate magazine, azbil.