Otsu City Public Enterprise Bureau Water Purification Management Center

Azbil’s Advanced Critical Monitoring for Safety was newly installed at the Water Purification Management Center of the Otsu City Public Enterprise Bureau, where water-related facilities are managed and operated, to predict changes in the level of water from a reservoir, thereby ensuring the stable supply of the water so indispensable to citizen’s lives. If a sudden problem occurs, like the failure of a pump at the reservoir, the system helps the city to take countermeasures immediately, and the system also contributes to maintaining a steady supply of high-quality water.

Factories and Plants Water and Sewerage Safety & Dependability Reliable Operation Operation Improvement Industrial Automation Control and Monitoring Systems and Software

Products/Services Provided

In addition to centralized facility monitoring, systematic water level prediction

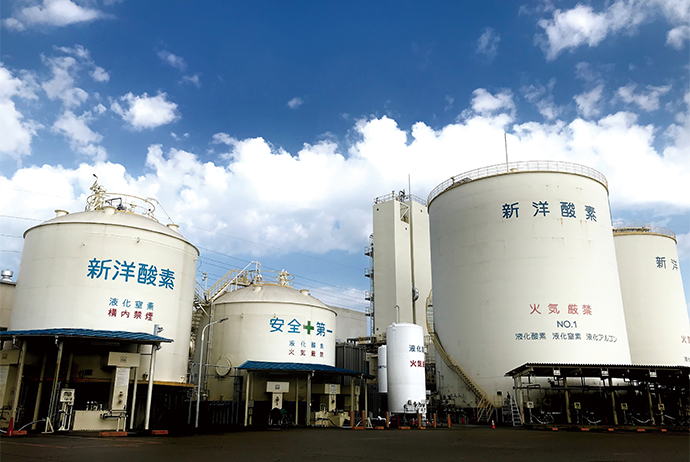

Otsu City, the capital of Shiga Prefecture, is located at the southwestern tip of Lake Biwa and is known as a city rich in nature, surrounded by mountains like the Hira range, Mt. Hiei, Mt. Otowa, and Mt. Tanakami. In Otsu City, the Public Enterprise Bureau is engaged in businesses related to the infrastructure that is indispensable to daily life. With the slogan “Partners who support your life,” the Bureau works day and night to supply high-quality tap water and gas, and to treat sewage. Above all, the water supply business works to provide a steady water supply to approximately 154,000 households and 340,000 people in the city.

The Bureau opened its Water Purification Management Center in July 2014. From its central monitoring system, the Center manages the operation of six water purification plants, water facilities such as booster pumping stations and distribution reservoirs, of which there are 137 in total, and the water quality at each location.

“For a water company, the most important thing to avoid is a water outage,” comments Takashi Mizuno, manager of the Facility Maintenance Section.

“Previously, two staff members were stationed 24 hours a day at each of the six water purification plants for monitoring. Since the number of available workers is decreasing due to the declining working population, we have now consolidated the monitoring work performed at each facility into one place and established a system that enables 24-hour monitoring with fewer personnel,” he explains.

“After the establishment of the centralized integrated monitoring system, if an abnormality occurred in the operation of a particular facility, it could be immediately checked from the Water Purification Management Center. However, in the event of equipment failure or other trouble, the estimated amount of water stored in the distribution reservoir, which temporarily stores water for distribution to houses, was still predicted by manual calculation. I was thinking that there was still room for systematization,” says Makoto Okuno, leader of the Maintenance Group.

For example, a typhoon or thunderstorm sometimes causes a power outage, and the pumps for pumping water into the distribution reservoir stop working. In such a case, the staff used to check the decrease in the water level and calculate how long it would take, if the situation continued, until the water level in the distribution reservoir dropped enough to cause a water outage. And based on the result, the staff took the necessary measures, such as repairing equipment or arranging for a water truck to supply water to each house.

“Many of our staff members work in the field, but we have the dilemma that we need highly skilled staff with abundant experience to do calculation work. Another problem was the psychological pressure on the staff if they made a mistake in calculation,” continues Mr. Okuno.

Predicting reservoir water levels for appropriate decision-making

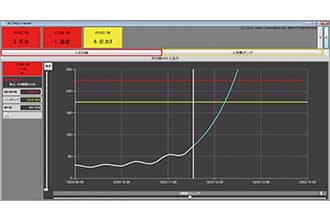

To address these issues, the Bureau considered introducing Advanced Critical Monitoring for Safety, provided by Azbil Corporation, to the Water Purification Management Center. This system can predict how the monitored target will change in the near future based on one data input point for the process variable being monitored.

“Azbil suggested that Advanced Critical Monitoring for Safety be used to detect and warn of abnormal fluctuations of water level in distribution reservoirs, or to help predict future fluctuations of water level,” says Seiji Yamamoto of the Management Group.

Thereafter, the Bureau started a trial use of Advanced Critical Monitoring for Safety in August 2018. The Bureau also began to actually monitor water supply facilities such as distribution reservoirs and pumps, and water quality, to verify the results calculated by Azbil’s system.

At that time, during the trial period, a water pipe at the distribution reservoir sprung a leak. Skilled staff members were away on a business trip for a water-related event in a rural area, and the small staff that remained had no choice but to cope with the situation.

“While the water level in the reservoir was dropping due to the water leak, the employees dealing with the problem were forced to decide whether to temporarily cut off the water and repair the pipe, or to pump water up to the distribution reservoir until the level was sufficient. At that point, Azbil’s system predicted that the amount of water stored would run out before repairs could be completed, leading to a water outage. So the Bureau decided to first secure enough water in the reservoir, and then do repair work, avoiding a water outage,” relates Takeshi Fukuchi of the Facility Group.

“Despite the sudden water leak, we were able to make a judgment based on the prediction from Advanced Critical Trend Monitoring for Safety. Afterward, we ran the data from that difficult period through the conventional calculation and got the same result as the prediction from Azbil’s system.”

“When we were faced with a leak from a water pipe, the system’s prediction helped us to quickly decide on countermeasures. Based on that experience, we decided to fully adopt the system,” says Mr. Fukuchi.

The Advanced Critical Trend Monitoring for Safety system running at the Water Purification Management Center can be linked with other companies’ monitoring systems. It can make predictions with only one analog data collection input point, without the need for complicated conditional settings, which is an advantage of the system.

Using Advanced Critical Trend Monitoring for Safety for water quality checks and other work

The Water Purification Management Center officially adopted Azbil’s system in May 2019.

“After the system’s official introduction, it predicts the situation a little further ahead, so we can now respond in anticipation of future movements. Before that, when a problem occurred, two people used to calculate the water level every 10 minutes, but now that process is automated and the technical staff is free to do work that only people can do. Also, in the event of a disaster, you can expect that breakdowns and stopped equipment will occur simultaneously in various places. It is difficult to handle such a situation by manual calculation,” remarks Mr. Okuno.

“By leaving the calculation to the system,” continues Mr. Fukuchi, “we can predict what will happen, understand how much time we have until it actually happens, and deal with it.”

Currently, in addition to constantly monitoring the water level of the distribution reservoir and predicting fluctuations in the remaining amount of stored water in case of equipment failure, Advanced Critical Trend Monitoring for Safety is used for the purification treatment at the water purification plant and for quality checking before water is sent from the distribution reservoir to people’s homes.

“Purified water must be maintained at the optimum pH level, which depends on the water temperature. The timing of chemical injection to control that value previously relied on the experience of skilled staff. Now, the system is also used for pH control and to check for residual chlorine before water is sent from the distribution pool to individual houses,” says Mr. Yamamoto.

The Center intends to continue promoting the use of Advanced Critical Trend Monitoring for Safety and hopes to apply it in a wider range of water supply operations.

“We want to find out quickly about abnormal facility conditions or water quality in order to reliably provide people with safe water. We look forward to Azbil’s proactive proposals and support in the future,” says Mr. Mizuno.

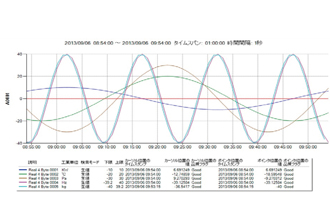

The monitoring screen of Advanced Critical Trend Monitoring for Safety is displayed on a large-scale monitor at the Water Purification Management Center so that the status can be checked at any time. If an abnormality occurs, an alarm is displayed on the monitor to alert the staff.

Azbil’s Plant Information Management System, which has been operating as a data management system since before the introduction of Advanced Critical Trend Monitoring for Safety. It centrally stores and manages operating data from various facilities, including data collected by other companies’ monitoring systems. It is used for monitoring and analysis of operating conditions.

Learn about the customer

Manager

Facility Maintenance Section

Group Leader (Chief Officer)

Facility Group

Facility Maintenance Section

Leader

Facility Group / Maintenance

Group

Facility Maintenance Section

Group Leader (Chief Officer)

Management Group

Water Purification Section

Otsu City Public Enterprise Bureau Water Purification Management Center

Otsu City Public Enterprise Bureau

Water Purification Center

- Address: 6-1 Yanagasaki, Otsu City, Shiga Prefecture

- Founded: July 29, 2014

- Business: Monitoring related to operation management and water quality of water facilities

This article was published in January 2022.